High -tech material requires compliance with all the installation standards of plastic ...

|

|

The wooden house is fashionable, beautiful, environmentally friendly, safe. That's why... |

The first thing that outsiders see and evaluate the owner of the apartment or at home input ... |

How to choose a tile cut - an indispensable assistant in working with tiles

Today, ceramic tiles are a very common finishing material, as it has a practicality, aesthetic appearance and durability. To lay it, it is necessary to have certain skills and special tools, for example, tile cutters. This is the simplest, and at the same time the most necessary device in working with ceramic tiles. When choosing a tile cutter, much depends on the characterization of the tile, so initially you need to buy tiles, and then a tool for cutting it. So how to choose the right tile cutter? In this article we will try to figure it out.

Content

- Titting cutter - design, features

- Five chosen cutter selection criteria

- Which tile cutter to choose manual or electric

- Tile cutting tiles

- Mark of the tile cutter

- Tiles cutter operating tips

Titting cutter - design, features

A tile cutter is a special tool that is used for cutting all types of stone, tiles, porcelain tiles, etc. Using this tool, you can produce a high -quality section of the tile, and you can get the cut line not, only at a right angle, but also vary the angle up to 45 degrees.

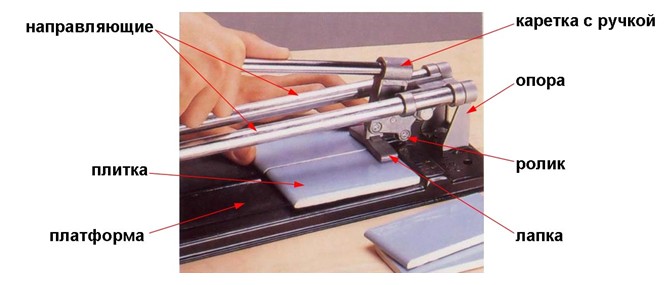

The design of modern tile cutter consists of a cutting element, an angler, a floating base and one guide. The main detail in the tile cutter is the cutting video, which is mainly made of carbide steel.

A distinctive feature of all tiles is the possibility of cutting both ceramic facing and floor tiles.

Agree, it is difficult to cut porcelain tiles with an ordinary grinder, and the quality of the cutting is not always very good. A tile cutter for kerome borderline can easily cut porcelain stoneware with qualitatively and relatively quickly.

Five chosen cutter selection criteria

When choosing a tile cutter, regardless of which constructive option was chosen, the tool should have 5 main criteria:

- Lack of marriage and other external defects. During the choice of the tool, you need to visually inspect it, check the build quality and the condition of the materials. After that, you should start the machine, check the quality of the engine, desktop, adjustment and if there are additional vibrations.

- Engine power. When choosing a tile cutter, you should take into account the volume of work, the thickness and hardness of the processed material and select the engine of the required power.

- The ability to cut the material at an angle. The adjustment of the angle should be performed quickly and simply, and the angle must accurately withstand without errors.

- Diamond disk. It is a weapon of tile cutter. It is important to know the quality, purpose and type of disk that is present on the device.

- The presence of spare parts. Nothing eternal happens, so this criterion is primarily relevant to all tools, but it is doubly relevant for a tile cutter, since finding spare, necessary details is not so simple.

Which tile cutter to choose manual or electric

Manual tile cutters characteristics, advantages, what to pay attention to when choosing it

Manual professional tile is the simplest and most convenient to use. Its strong design allows you to cut the tile exactly in a straight line. It is used for tiles with a thickness of not more than 1.5 centimeters, and a special tile cutter up to 40 centimeters long is used to cut 8-mm wall tiles.

Manual lapcids in design are:

- roller;

- mechanical;

- on bearings.

Roller tile cutterit is quite simple in the design, the cutting element is precisely the video made of solid alloy.

Mechanical tile cutter It has a hard carriage, which allows you to cut the material with particular accuracy, including tiles of a fairly solid type.

Tiles on bearings Designed for processing a particularly durable tile up to 16 mm thick. This tool has the ability of a very soft move, since there are bushes on 2 bearings.

When choosing manual tile cutter, attention should be paid to the strength of the frame, the length of the tool and smoothness.

The base of this tool should be tough to avoid depreciation during tile cutting. The stronger the handle of the tile cutter, the more powerful you can press on the lever. It is better not to buy too small a tile cutter, but to purchase a universal model that is suitable for both floor and wall tiles.

The bulk of the tile cutters are equipped with bearings to give smooth smoothness. There are, of course, models without bearings. In this case, during the choice, you need to make sure of the quality of the working body.

Advantages of manual tile cutters:

- Independence from electricity. Compared to electrical tile cutters, this is a significant savings. In addition, manual tile cutters can be used in any weather conditions, even with air humidity up to 90%.

- Small size. For their operation, it is not necessary to deduct an additional room or part of it, a small section of the floor or table is enough.

- The ability to move from place to place. Due to their small weight (0.2 9 kg), they are very convenient and practical.

Electric tile cutter - types, characteristics, choice of choice

During large volumes of work, it is best to use electric tile cutter. Unlike manual tiles, the electric cuts the tile much more accurate, faster and with less losses. Tiles during cutting can burst due to an increase in temperature, so electric tile cutters are equipped with water and air cooling systems.

A tile with water cooling is carefully treated with tiles, capable of gently, even without scolts to make cuts. The liquid that is located in the tank under the engine should be supplied to the cut zone forcibly and with the adjustment of the feed.

During operation, it does not overheat and does not fail due to the constant supply of water during operation.

Advantages of electric tiles:

- The ability to cut at an angle of 45 degrees, which is important when laying the angles of the walls.

- Accurate, without rough edges, incision

- The minimum time spent on working on one tile is spent less than a minute of time

- Light, convenient cutting of both porcelain tiles and stone.

There are two types of electric water tiles:

- with the lower engine location;

- with the upper engine location.

A cutting tool with the lower engine location is very compact, it can work in small rooms and is able to cut the tiles of almost all sizes. For more accurate and convenient cutting, tile cutters are used in which the engine is located at the top.

During the choice of electric tile cutter, attention should be paid to the following parameters:

- The depth is cut. It should vary within 3 - 4 cm.

- The length of the cut. It should be within 50 cm.

- Engine power. This indicator should be selected depending on the purpose of the tool and the type of tile.

- The diameter of the cutter. Cars are mainly used with a diameter of 18-20 cm.

Tile cutting tiles

Before starting work, it is necessary to put on special protective glasses and headphones to protect the sensitive organs from fragments and excessive noise of the tank cutter.

It is necessary to make sure that the wheel is securely fixed and does not move from the side, as this can lead to an uneven incision. You also need to check its degree of wear, if there is a need to replace, it is better to purchase a new wheel.

If manual tile cutter is used, a certain amount of oil should be applied to the guide frame of the tool.

To make a high -quality incision using a tile cutter, first you should apply a cutting line with a marker on the tile. Then you need to put the tile on the basis of the tool, securely fixing it to avoid vibration. Next, with one quick movement, draw a knife along the entire length of the finishing material. The cut is carried out on the front side of the material. Moving the cutting material is best with two hands in order to make an uniform incident and avoid the formation of fragments.

During the touch of tiles and a tile cutter knife, the pressure force should be minimal. No need to press the tiles hard, as this can lead to its split. Next, it must be gradually increased, reducing to the end of the tile. If cutting is carried out for the first time, then it is best to stock up on several tiles in order to practice.

The tile cutter has sponges made of metal. They are used to separate two parts of already cut tiles. With these sponge, you should carefully press the tiles on both sides, it should be divided by a slight click.

If there is a need, then the cut edge of the tile can be tied with sandpaper or grinding stone.

Mark of the tile cutter

Rubi tile cutter is capable of quickly, and most importantly evenly cut all types of tiles and porcelain tiles.

The advantages of Rubi tile cutter:

- There are whole, steel guides. They guarantee excellent cutting quality and a long service life.

- The most effective and convenient bushing systems are used. This excludes the use of bearings that can go to the place and break.

- The tiles are made of very durable aluminum, which makes this tool at the same time light and reliable.

Matrix tiles are used to cut tiles up to 1.4 cm thick and 30-60 cm long. This tile cutter has only 1 guide rail, which covers the supporting carriage on both sides. It moves with the help of a ball -bearing mechanism.

Matrix tiles have a special coating of the rail and alloy, which provide reliable clutch of the rail and ball mechanism.

The tile cutter is used for cutting tiles both at a straight, oblique angle, and for combined corners.

There are two types of tile cutters of this brand: an automatic drill machine and a tile cutter with a manual mechanism. The tile cutting machine can operate in a multifunctional mode, is able to determine the diameter of the tile and the correctness of its fastening using CNC.

Tiles cutter operating tips

While working with such a building tool as a tile cutter, it is necessary to observe some rules to exclude the possibility of injury.

Shards that form during work can damage the eyes, so you should use protective glasses. No need to bring your hands too close to the cutting tool. If electrical equipment is used, then you need to be especially careful.

Electric tiles do not tolerate high humidity. It is important not to overload the tile cutting, trying to cut very quickly or very thick tiles. Through this engine, tiles can overheat or split.

Particular attention should be paid to the cable of electrical equipment, it should not interfere under the feet, twist or bend.

he cuts very quickly. I have no words

he cuts very quickly. no words, and weighs not hard

I am engaged in the repair of cottages.

I am engaged in the repair of cottages. They gave a design project such that the suitable tile could not be found anywhere. Fortunately, I discovered it on the website http: //montwesste.rf/. The choice is very large and the prices are lower than you can expect. I liked the clear work of the manager. Clearly formed the order, did not confuse anywhere, although there were many positions. He competently advised the best solution.

Useful article, I see

Useful article, I look at the tile cutters now, so far I only like the model of Dnipro-M in price and capabilities.