Today there is nothing much more traditional than decorative tiles ...

|

|

Today in the world of flooring, a completely new floor material has appeared ... |

Everyone sooner or later faces the problem of insulation of the house. Because of... |

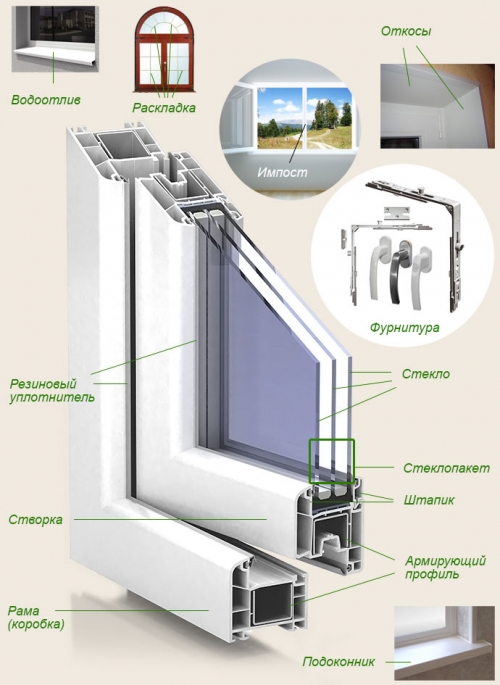

How to check the quality of plastic windows

The quality of the quality of plastic windows for the consumer is paramount, since window structures are installed not for one year, but for a couple of decades at least. High -quality windows must certainly retain heat in the house, pass the light well into the room, reduce the noise level that penetrates from the street, close tightly and be convenient to use. Therefore, it is so important to know how to distinguish plastic windows of good quality from the second-rate PVC material.

Content:

Plastic windows quality standards

A sign of high-tech production of plastic windows is the presence of the DIN EN ISO 9001 certificate manufacturing company. A similar control system guarantees maintaining stable properties at the required level and the correspondence of the product to all standards and quality signs.

Window profile

When buying metal -plastic windows, it is recommended, first of all, to pay attention to the profiles that were used in their production. On the world market, several varieties of profiles are currently represented, which are branded by manufacturers: these are the German quality windows Rehau, Veka profile, Proplex profile, Tryba and Queer profiles. The main difference between profiles of different brands is the recipe for the production of plastic.

The main problem of poor -quality profiles is their inability to solve problems associated with ensuring reliable isolation of residential premises from penetration from cold and extraneous noise. Poor -quality profiles of metal -plastic windows will be blown through and through all the winds.

Heated PVC during the manufacture of window profiles is passed through a special form. As a result, a hollow profile is obtained, divided into chambers with jumpers. Therefore, you have to decide when choosing plastic windows with the number of internal chambers in the profile of through holes, which are designed to play the role of peculiar air pillows. Often, inside the chambers of plastic windows there is a layer of insulation.

According to construction standards, in residential premises it is allowed to use at least a three-chamber PVC profile. Two-chamber PVC profile can only be used for glazing non-residential rooms. However, the number of cameras in the profile is not limited only, usually from this number it only begins. Today, manufacturers of plastic windows begin to increase the number of cameras in plastic profiles, offering a five -chat profile.

The larger the number of chambers and, accordingly, the air layers in the profile, the plastic windows, ultimately, will be warmer. How many cameras should be in the window profile should be decided based on climatic conditions. The colder, the more cameras are required. However, it is still advisable to put a five -quality profile only in the Far North!

A number of manufacturers, on the contrary, instead of increasing the number of cameras, it is customary to put an additional frame for insulation. Since the plastic itself does not withstand a large load, the PVC profile is customary to reinforce, inserting a metal frame (enhancing circuit) into the profile. For these purposes, as a rule, the widest central camera is used.

Metal should not be in thickness less than 1.5 millimeters. The best material for creating a reinforcing profile is a galvanized steel, in which case the windows can withstand a high load. With the use of simple steel, red flowing over time can occur over time. The form of the reinforcing profile is also important, the closed circuit is considered ideal, which in the cross section is a square. It is also often used for reinforcement and the P-shaped profile.

The next important point that affects the quality of metal -plastic windows is the width of the PVC profile. The structural width of the profile is usually dependent on the number of cameras. This parameter for a 3 -chamber profile is approximately 57 63 millimeters, for 5 chamber - up to 70 millimeters, and sometimes up to 120 millimeters.

It is also important to know what thickness profiles can be installed without loss of quality. Everything here is just the larger structural width of the profile, the thicker you can insert a double -glazed window with a large number of cameras. Therefore, the greater the width of the window profile will be, the finished plastic windows it will be warmer.

Furniture to the windows

When choosing windows, customers are, first of all, the features of double -glazed windows and profiles. However, under the influence of weight and mechanical loads, it is a fittings. The usual window for the period of its service will open at least 50 thousand times, therefore reliability, durability and quality of windows will depend on the quality of accessories.

Window fittings are a complex locking mechanism. These are brackets, loops, traction, connecting and other elements (more than a hundred parts), providing tight fit to the frame, opening and closing the plastic window in different modes. At a low price, accessories are usually offered, which is made of soft metal, and sometimes partially made of plastic.

The windows that are collected using such accessories will have to be adjusted all the time. And after a couple of years, they will need their complete replacement. Therefore, choose the working mechanisms that are made of durable metal. It is not customary to choose accessories separately from the window, because the basic accessories on it have already been installed.

But in addition to the standard set, which allows the window to open and close, you can organize many auxiliary options: a rotation limiter that ensures a fixation of the window sash in an extreme open position; a restraint of leaning the sash, which provides safe ventilation; a slit ventory, which allows a few centimeters to open the window; Microlift, which allows you to raise a sagging sash, thereby unloading the loops.

You can also choose several options for ventilation, say, micro -spacing, which allows the windows not to fog, simultaneously ventilate the room and are not afraid of drafts. There are several types of micro -spacing when you can open the sash by about 3 - 55 millimeters.

Double -glazed windows

The lion's share of the window opening will occupy precisely the double -glazed window, so you need to very seriously approach its choice if you are interested in the quality of plastic windows. The double -glazed window is a block of several glasses, between which there are sealed chambers. The double -glazed window along with the profile is responsible for the sound permeability and thermal insulation of the window. Poor -quality double -glazed windows nullify all the advantages of the best frame.

When choosing a double -glazed window, you need to pay attention to the following points:

- According to existing norms, the thickness of the glass should be at least 4 millimeters. However, often recently, you can run into windows with a glass packet, in which a three is set instead of the four.

- For good thermal insulation, you need to use multi -chamber double -glazed windows at least two -chamber. Two -chamber double -glazed windows will save you from excessive street noise and will help save the heat into the home. This design consists of 3 glasses, between which air chambers are located.

- Triplex is glass, which consists of a pair of layers and is laminated with a special film, which is located between the glasses and ensures safety, since it does not fly apart with physical exposure. In addition, the triplex is characterized by an increased level of soundproofing and does not miss ultraviolet radiation.

- An ideal option for those owners who are looking for price-quality windows and want to increase thermal insulation in their house will be the order of double-glazed windows that are made using energy-saving I-glass. A special coating has been applied to it to save heat, which does not pass infrared rays and allows you to keep cool in the room in the summer, and in winter cold - not to release heat outward. Even a single -chamber double -glazed window with such glass will perform the function of heat saving, because the special coating heats inward, not allowing it to go through the window.

- To protect yourself from sunlight, you can buy glasses with a mirror coating, which is applied by spraying metal oxide. Another technique to protect from the Sun is the use of painted glasses. In addition, stained glass can be placed in the glass -window.

If you combine the double -glazed window and profile, you can get these options:

- Three -chamber profile and single -chamber double -glazed window. This is a fairly economical option that is used for non -residential premises, and for a window that goes to the loggia or a glazed balcony.

- Three -chamber profile with a two -chamber double -glazed window. In this case, you get plastic windows price-quality with excellent heat-insulation and noise protection that it is customary to install if you live in a well-heated house.

- A five -chamber profile with a two -chamber double -glazed window. This decision can provide you with maximum protection against cold weather and noise. This option is perfect for those houses that are located near the tram and railway tracks, as well as noisy roads.

Seals

The windows from different manufacturers differ in the color of the seals, which are laid on both sides along the edge of the double -glazed window, as well as at the junction between the sash and the frame. The black seal perfectly emphasizes the whiteness of the profile itself. In addition, a black seal will last you much longer than gray or white, which are also present in different specialized systems.

White and gray seal will lose its elasticity after 2-4 years and will become dirty, especially if your house is located near the passing line. It will not work to wash the seal from the city smog, but on the black seal of these contaminants it is simply not visible.

The seals are made of special rubber, rubber, rubber or silicone. Their characteristics are one of the main factors that provide the heat -insulating properties of the plastic window. The most effectively ensures sealing, sound and thermal insulation of structures, which is made on the basis of EPDM polymers and reduced in PVC.

Plastic windows installation quality

Of course, the quality of PVC windows will directly depend not only on the characteristics of the profile, double -glazed window and accessories, as well as on competent installation. Many problems that arise with plastic windows are explained by their improper installation. Therefore, it is so important to know how to check the quality of plastic windows after installing them.

Strong mount

The main condition for success is the correct measurement of window blocks and compiling a sketch of future glazing. It may seem at first glance that it is quite simple to measure the height and width of the window opening, but here it will not be possible to do without professional skills, skills and experience.

The manufactured windows according to incorrect sketches may not fit the opening, and then they will need to be redone. Before installing a plastic window, it is necessary to check the correspondence of the brought products to the openings, since you can stay with open openings in case of an error of the measurer.

The window should be firmly fixed because its weight reaches 100 kilograms. Fasteners are the most vulnerable place in the installation process. We warn you against deception, for example, that at least 14 fasteners are spent on the installation of a double -leaf window with a partition, as a rule, anchor plates. The consequences of savings in this matter are reduced to shedding a window, a skew of the sash and the appearance of microcracks in the installation seams.

If you are interested in how to determine the quality of plastic windows after installation, then it is worth checking the density of closing the window. To do this, you may not wait for a change in the direction of wind or frost. You should just take a newspaper sheet, place it between the window and the frame and close it with the help of accessories. Then you need to try to carefully pull the clamped sheet. He must stretch out hard.

Repeat such an operation is recommended around the entire perimeter. If in some places the sheet does not stretch at all, in others it can be reached without any effort, and there is no defects, then it is necessary to adjust the accessories. In addition, when turning the handles, you should not feel unnecessary freedom of movement, on the contrary, there should be some effort.

It is also worth checking the vertical installation of the window structure. When opening, the window should not move independently towards the opening. If you find this defect, you need to think about reinstalling. Remember that you need to check the presence of end plugs at the thresholds and window sills. Sometimes they simply forget about them, or they are shorter than necessary.

Installation seam

When installing a plastic window, it is necessary to observe the normative distances between the frame and the wall - 1.5-5 centimeters. This is required for the correct arrangement of the mounting seam, which consists of mounting foam, sealing ribbons and sealants. Such a seam performs the function of a layer between a warm frame and a cold wall. If you install a plastic window of good quality close to the wall, then in the winter you can find out what the freezing of the window is.

The main element of the mounting seam is a special hardening foam. Along with household foam, brands that are designed specifically for windows are presented on sale. They are divided into winter and summer. Pay attention to the features of their use. When filling out installation joints, voids are not allowed, and it is forbidden to cut off the frozen foam on the street side. After all, in this case, she will lose her protective crust and open hygroscopic pores, in which moisture accumulates over time, freezing in winter and destroying foam.

But even the foam that has a crust needs to be protected. The windows that are installed only on foam, in a few years, will show signs of aging. The frames in the opening are moved, causing air exchange through microcracks between the room and the street. As a result of a zone of high humidity, on slopes and frames, a fungus and mold appear. In order to protect the mounting foam, it is customary to use sealing tapes or sealants.

As you know, plastic is able to expand with an increase in temperature, say, in the sun. These changes are insignificant, but are still transmitted to mounting seams. In order to protect them from deformation and frame in the opening, give additional stability, you need to put special support pads made of wood or plastic impregnated with an antiseptic. The absence of pads contributes to a violation of sealing the mounting seam.

On elements of structures and slopes, there should be no traces of mounting foam. If the foam is present, then, then the protective film was shot earlier, that is, before the installation of the window. You can remove the mounting foam after drying with a small skin with future polishing with special paste. However, if the material is rough, not smooth, then this technique is not suitable, because there will be a difference in the structure of the surface.

And finally, before deciding which windows are better in quality, remember: a high -quality plastic window cannot be cheap! By saving money today, you will encounter in the near future with many problems of low sound insulation, poor ventilation that provokes windows, condensation and damping of wall surfaces near the plastic window, low color resistance of window frames and their yellowing, deformation of the window and the difficulty in opening-plotting.

a stupid site, because Turning on

a stupid site, because Turning it on, he speaks, and turning on the video, now 2 votes and nothing is clear.

great article! all

great article! Everything is competent, nothing superfluous, everything is very clear. In one article I learned about everything that I read in all the previous ones. Thanks.

Already placed an order in

Already placed an order at http://oknaplas.ru/, in the apartment all the windows changed. Now in the country they decided to replace with plastic ones. As for the first time, the execution of the order was very pleased! The windows are high -quality and require minimal post -ontal work. Separate gratitude to the master Alexei - minimal destruction, accurate and conscientious work, answers to all questions that concern us. We were glad to cooperate! We recommend it!

Thanks for the useful and

Thanks for the useful and interesting article!

One of the important components of any home is the windows, and in order to understand which windows to choose, you need to study information about them. Then it will be possible to buy high -quality, durable and reliable windows that will maintain warmth and comfort in the house.

First you need to study and get acquainted with the materials that manufacturers produce, as well as find out reviews about the company itself: https://postroem-vse.ru/kak-vybrat-plastikovye-okna/