Topping the goal of creating an unusual interior, using time tested by time and ...

|

|

By purchasing an interior door, it is impossible not to face the problem of choosing a door ... |

During the repair period in the premises, the repair of ceilings is given great attention .... |

DIY metal ladder

A home master should be able to make an indispensable direct ladder in the farm. The design must comply with the main safety and reliability requirements. To create a solid staircase, you need to correctly choose the components, get acquainted with the technology, develop a drawing and make assembly. The stages of manufacture of the attachment are described in the article.

- The bailiff is an indispensable thing on a personal plot

- Constructive requirements for ladders of the prefix type

- Types of structures of ladders

- Selection of material for the manufacture of stairs

- DIY ladder from a profile pipe

- How to make a borely wooden staircase with your own hands: specialists' advice

- Safety precautions when working on the ladder

The bailiff is an indispensable thing on a personal plot

In the country or household territory, the ladder will be provided when performing work carried out at a height. The seasonal pruning of fruit and park trees, tinting window frames, harvesting and other events are not dispensed with without garden equipment. Basket stairs are mobile, low weight and simplicity of design. In fact, these are two supporting beams fastened together by crossbars.

In economic stores and construction markets, a wide range of modifications of bailiff stairs from different materials is presented. Buying a high -quality large -sized model is quite expensive, and the reliability of cheap stairs causes certain doubts. Therefore, many home masters often raise the question: how to make a ladder with their own hands?.

The expediency of an independent structure is fully justified, since the scope of use of the ladder is quite multifaceted:

- performing repair and construction facade work;

- repair of electrical wiring in a private house;

- installation of electricity meters, monthly relief of readings;

- washing of window glasses on the first and second floor;

- decoration of the facade of the house;

- cleaning of drain pipes, stormwood;

- performing small repair of roofing material.

Despite the significant advantages, the mobile ladder has some disadvantages:

- low carrying capacity of the structure are not designed for loads of more than 200 kg;

- narrow area of \u200b\u200bthe support reduces stairs stability;

- not very convenient operation due to the lack of railing, steep rise and thin steps.

Metal stairs are considered the most durable and durable. A simple model can be done independently. To perform work, it is advisable to have welding skills.

Constructive requirements for ladders of the prefix type

The main requirement for attached models, as well as for other varieties of stairs, is security. When planning the design of the stairs and performing calculations, you should adhere to a number of basic rules:

- The maximum ladder length of such a modification is 5 m. However, this restriction is relevant for wooden models. Metal stairs can be higher due to the strength of the material.

- In the manufacture of the stairs, it is advisable to provide for the installation of special nozzles: uniform hooks, steel pins and rubber lining. These elements improve the stability of the structure.

- The optimal step of the steps is 30-35 cm, the minimum distance is 25 cm.

- The width of the span is not less than 40 cm.

- The optimal surface load 200 kg per meter is square.

- Constructive details should not have pointed untreated edges and metal burrs.

- In the manufacture of ladders and advanced modifications of stairs, special castle joints are used, which prevent spontaneous opening/closing the structure.

- For the convenience of moving large -sized models, wheels are installed on the supporting legs. In this case, it is necessary to provide for the presence of a lock so that during operation the staircase does not leave under the feet.

Important! According to safety measures, checking the strength characteristics of the ladder should be carried out annually. The design is installed to the wall at an angle of about 70 ׄ, and then a weight weighing at least 100-120 kg is alternately on the steps.

Types of structures of ladders

There are several types of ladders, each of which has structural and operational features.

Right -line simple stairs with fixed dimensions. An uncomplicated model of two support beams and attached steps. It is very simple to make such a bastard staircase with your own hands. Folding and sliding models are more functional and reliable.

Folding stairs (steps) consist of several parts connected by hinges. The main advantage of the model is compactness and the possibility of storage in a compact room. Legislators with the site are more convenient to use than direct designs. For the manufacture of a folding ladder with your own hands, aluminum alloys are usually used, so the weight of the ladder is reduced.

Folding modelsThe most in demand when arranging attic premises. The staircase saves the space of the lower floor enough to pull the lower step or a special handle and the design will completely deal.

Disadvantages of folding modifications:

- the complexity of design, assembly and installation;

- the need to use expensive components;

- low strength of the structure consisting of several elements.

A sliding staircase with the possibility of adjusting the height. Models consist of two or three sections, fasteners, guides, rollers and height fixers. So that the staircase does not fail at the right time working mechanisms must be regularly lubricated.

Selection of material for the manufacture of stairs

Direct stairs today are made mainly of metal, and traditional wooden structures become less in demand.

Distinctive features of metal ladders:

- for self -manufacture, aluminum, stainless steel or alloy of metals is usually used;

- high strength, resistance to moisture and mechanical damage;

- aluminum is not subjected to corrosion, and structures from another metal need to be processed with protective equipment;

- high carrying capacity;

- practicality and durability;

- for the manufacture of a metal ladder with your hands, the experience of welding will be required.

The wooden staircase is simple in manufacture, but demanding on storage and operation conditions. With too dry air, the wood is drying out, the material weakens, and cracks may appear. Under the influence of high humidity, the wooden staircase is rotted. To reduce the risks of destruction of the structure, it is necessary to regularly process the wood with protective means.

Important! Wooden ladders withstand the load up to 150 kg.

During electrical work, the material from fiberglass is often used to use sliding stairs from fiberglass from electric shock.

DIY ladder from a profile pipe

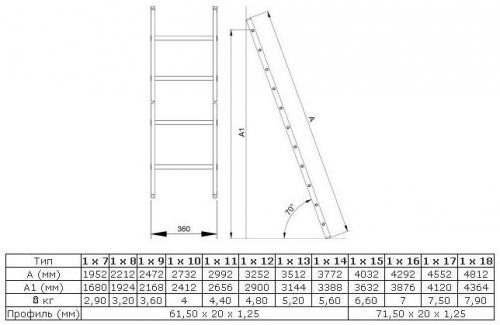

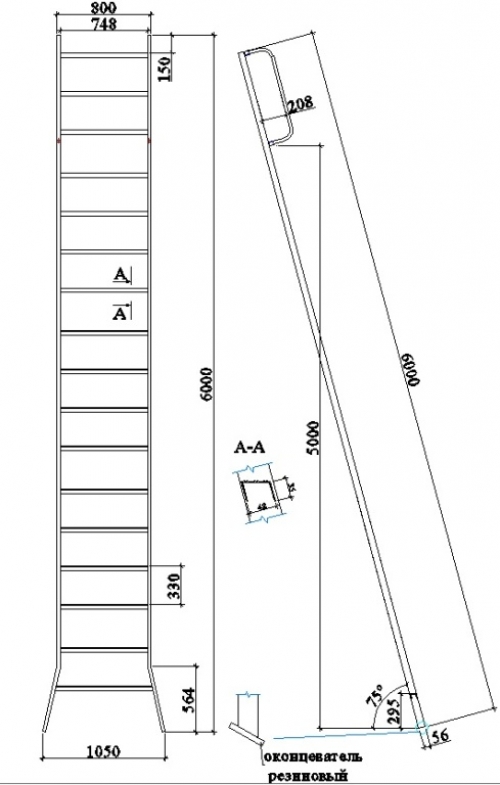

Drawings of bailiff stairs

The manufacture of ladders with your own hands begins with the development of the drawing. It is necessary to schematically display the main parameters of the staircase:

- height and width;

- parameters of the material used (diameter/section of metal, etc.);

- staircase;

- type of fastening;

- type of support.

As an example to create a sketch, the existing schemes from the Internet are suitable.

Do -it -yourself binding metal staircase: drawings of various modifications.

Attic ladders with hands: drawings and schemes. Video

Necessary tools and materials

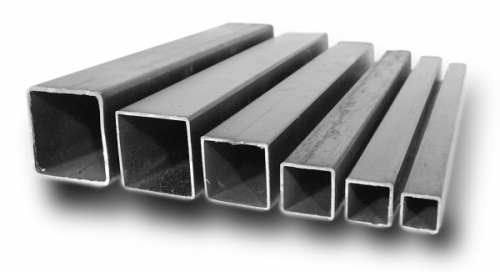

To create a simple metal staircase, the following materials will be used:

- profile pipe two cuts of 2.5 m, diameter 4*4 cm;

- cuts from a profile pipe with a length equal to the width of the stairs (30-35 cm) 10 pcs.;

- square metal plates in size 4*4 cm 4 pcs .;

- steel corners 20 pcs.;

- primer for processing metal surfaces;

- dye.

From the tools at hand, you must have:

- hacksaw for metal or grinder;

- square;

- grinding machine or sandpaper;

- a wide durable table for laying out parts of the structure.

The order of assembly of the ladder

Consider step by step how to make a ladder with your own hands. The assembly scheme is as follows:

- Put metal supports on the table. Control so that the elements are located in parallel in relation to each other at a distance of 30 cm (width of the stairs).

- Apply marks for installing steps with a step 25 cm.

- According to the marks, they will additionally fix the crossbars.

- Procate two cuts along 30 cm to the supports from below and from above. The result should be a rectangular frame.

- The crossbars are sequentially laid on the corners and weld with a double welding seam.

- To the ends of the supports super and below weld metal plates. This measure will prevent land, garbage and water into the supports.

- Welding seams can be cleaned with a grinding machine.

- Grind the stairs and leave the metal until completely dry.

- Cover the design with paint, and after complete drying, apply the second layer of LKM.

How to make a borely wooden staircase with your own hands: specialists' advice

When creating a direct staircase or ladder made of wood, the following points must be taken into account:

- For work, it is better to use coniferous wood. It is unacceptable to make a staircase from wooden beams if they have transverse or longitudinal cracks. Broaches with signs of decay, large bitches are rejected.

- The choice of the minimum section of the support beams depends on the height of the constructed structure.

- Before assembly, all wooden parts are treated with an antiseptic.

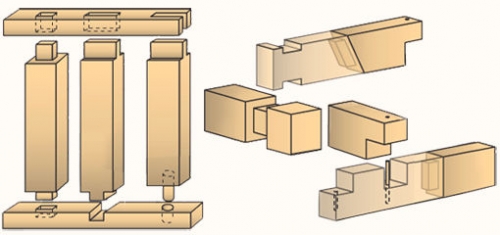

- Design elements are fastened with each other in one way:

- the overhead method of the steps are fixed to the supports using nails and screws; This option is considered the simplest, but not reliable enough;

- the levels of the crossbar of the steps are installed in samples prepared in support beams;

- shipping joints in bowstrows are made, and the bar through the edges; Fixation can be performed at an angle.

Advice. The stud joint in wooden structures is the most durable. It will turn out to prepare a nest and spike with a bit, kiyanka or electric drill in a stand.

Safety precautions when working on the ladder

Basic models are not equipped with an independent support, so knowledge of the basics of safety precautions will help prevent the fall and injuries.

- Long work at an altitude of more than 1.5 m must be performed with a safety belt.

- The staircase cannot be installed on boxes, tables and other items to increase its height. It is better to grow two separate ladders with metal clamps. Before work, the structure must be checked by a load of 150 kg.

- The safest installation angle is 60. When placing a stairs under 75 and above, it is advisable to fix it on top.

- To prevent sliding when lifting, the steps must be equipped with rubber overlays.

On the ladder is prohibited:

- raise heavy objects;

- pull the electric wire;

- use overall welding devices and electrical equipment;

- move without adhering to the stairs;

- at the same time rise more than 1 person.

Compliance with the technology of design and operation of the ladder is the key to the safe performance of various works at altitude.

Production of a ladder from metal profiles: video