The main advantage of porcelain tile is its high quality and duration ...

|

|

Today, many developers choose the construction of a columnar under their house ... |

Theft has long been a craft for many. On police reports most often ... |

URSA insulation: characteristics, properties, installation

Manufacturers of traditional and modern building materials are still not able to guarantee their high thermal insulation properties. Often, in order to achieve acceptable indicators in this direction, one has to increase the thickness of the ceilings. This leads to the fact that the mass of the structure becomes exorbitantly large, and, therefore, the requirements for the soil, foundation, frame and other elements will be presented more stringent. The use of heat -insulating products will help to avoid such problems. Heater is designed to reduce heat loss and effectively keep the microclimate in rooms comfortable for others. They have a relatively small specific gravity, which allows you to reduce the consumption of building materials, reduce energy consumption by heating the structure, and also increase the level of sound permeability of the walls. The article will talk about the URSA insulation.

Content:

- URSA manufacturing company

- Features of the URSA material

- Technical characteristics of the URSA mineral insulation

- Technical characteristics of URSA insulation from EPS

- The main advantages of thermal insulation of Ursa

- The scope of URSA insulation

- Installation of thermal insulation of Urs

Of course, all this is true only if the choice was made in favor of proven insulation with maximum quality and reliability.

It is worth noting that thermal insulation properties are not the only characteristics that should be paid to. It is also very important that indicators such as strength, durability, wear resistance, fire safety and resistance to atmospheric phenomena have as higher as possible.

UrSA photo

The manufacture of insulation is a leading type of activity for many companies, but only units boast of truly high-quality products that would satisfy all the requirements of even the most demanding consumers. The URSA company can rightfully consider itself a representative of exactly such organizations. What are the main differences in this manufacturer and others?

URSA manufacturing company

Despite the fact that officially the URSA company begins its history only in 2002, it has many years of experience in creating reliable and effective thermal insulation materials.

- The history of the company should begin with the Uralita concern (Spain), which was formed in 1907 and was engaged in the production of fibrous cement. It is noteworthy that the raw materials for products were exported from the Urals, which was reflected in the name of the brand (the name can be translated as Ural stones).

- In 2002, Uralita united with Pfleiderer (Germany), which at that time had more than a centuries -old history and was the leader in the production of insulating products in Germany, Europe and Russia. At approximately at the same time, a merger occurred with another trademark - Poliglas, which is engaged in the production of extruded polystyrene. Perhaps this determined the further direction of the concern.

- Today, the Uralita production group has four main directions. The activities of the URSA subsidiary are the production of construction insulation products. Industrial enterprises and retail chains are located in Europe, Russia, in the countries of the Middle East and Africa. So, for example, products based on extruded polystyrene foam are manufactured at factories in France, Italy, Germany, Spain and Russia. Mineral thermal insulation is more popular, enterprises in eight countries are engaged in its manufacture (Poland, Belgium, Slovenia, Spain, Germany, Turkey, France, Russia).

- The URSA company is trying to expand the range of its products annually and go to new sales markets. The brand logo (white bear and bear cub) symbolizing heat and comfort, recognizable in many countries around the world. Products manufactured are used both in primary construction and for the reconstruction of existing buildings. These are safe materials that have high environmental friendliness. It is thanks to this indicator that the scope of their use was significantly expanded.

- In Russia and the CIS countries, this brand is represented by the company of Ursa Eurasia, whose production centers are located in the cities of Miracle and Serpukhov. The factories are equipped with modern equipment produced in Slovenia, Denmark, Germany and the Czech Republic. All products undergo mandatory quality control and have all the necessary certificates.

Features of the URSA material

Under the URSA brand, two varieties of products are available:

- based on extruded polystyrene foam (EPS);

- based on fiberglass.

Thermal insulation from EPS

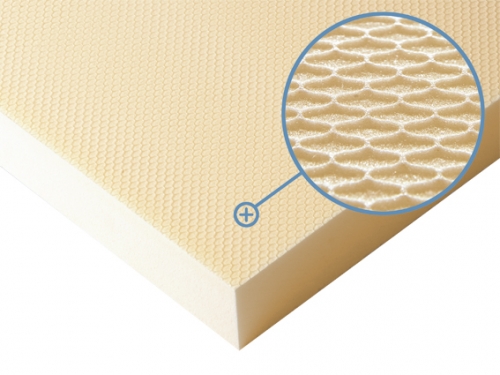

- It is a synthetic product that is produced by extrusion. That is, under the influence of elevated temperature and pressure, polystyrene granules are mixed with special foaming substances. Then, the molten mass is squeezed through the extrusion head of a high -tech machine.

- The result is material that has excellent strength, low thermal conductivity and low specific gravity. At the same time, it has a closed porous structure (that is, cells with a diameter of about 0.2 mm on the surface are located evenly and have a closed look), which allows you to perfectly resist moisture.

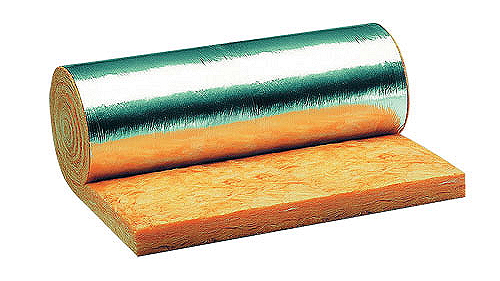

Fiberglass -based insulation

- They are a canvas created from a mixture of quartz sand, dolomites and soda. After the components were melted at high temperatures, special substances are added to the composition that can glue the ingredients into a single mass. Next, the molten solution is pushed through the filter of the extrusion apparatus. The resulting glassons have increased strength, do not beat and do not break even when stretching and flexion.

- URSA company marks its products depending on the material of manufacture. So, the fiberglass products received the Geo prefix, as it refers to environmentally friendly and safe products. Also, on the basis of glassons, a technologically new product called Pureone was created. The composition of such insulation uses acrylic components, and it is recommended for use in medical and children's institutions. And finally, thermal insulation based on extruded polystyrene foam received the XPS marking - this is a reliable, durable material that guarantees excellent heat and sound insulation.

- To date, the manufacturer of Ursa offers consumers three varieties of mineral insulation and one type of isolation based on EPS.

Technical characteristics of the URSA mineral insulation

Mineral heaters include all materials created on the basis of natural components, that is, from fiberglass. Such products are produced with rolls or slabs (in one package there can be 5-24 sheets).

There are no phenolic binders in the composition, which means that the products belongs to environmentally friendly types. In addition, thanks to non -combustible substances that are used in the creation of insulation (sand, soda, and so on), the mineral thermal insulation of Urs is characterized by an increased degree of fire safety. The warranty life is 40-50 years, but, of course, is not limit.

- The density of the insulation.This indicator varies in the range from 15 kg/m3 to 85 kg/m3. Depending on the scope of use, certain products should be selected. So, for private housing construction, there are enough materials with a density of up to 30 kg/m3, if it is planned to use thermal insulation in severe conditions, for example, by water transport, it is recommended to use denser views.

- Specific thermal conductivity.Products have a low coefficient of thermal conductivity, this indicator is in the range of 0.030-0.046 W/MK. That is, it is precisely such a amount of heat that the material passes through itself during operation, which indicates the high characteristics of thermal insulation from the company URS, capable of ensuring effective heat saving of almost any buildings.

- The temperature mode of application.This characteristic shows at what temperatures the insulation can perfectly maintain its properties. The manufacturer guarantees that the material can be used at minus ambient temperature from -60 degrees, as well as with a plus indicator up to +310 degrees. It is about air temperature, since the recommended temperature should not exceed +100 degrees on the surface of the product (some species up to +180 degrees). In general, we can say that the insulation is universal for operation in any climatic areas.

- The dimensions of Ursa insulation.Mineral insulation is produced in various variations, in the form of rolls or plates. The thickness of the products can vary from 5 to 20 cm, width 60 and 120 cm, the length of mats is from 3 to 18 m, and the length of the sheets is 1.25 m.

Mineral components -based materials line

- The heat insulator based on mineral fiberglass is characterized by increased environmental friendliness, and due to the absence of volatile compounds, it is completely safe for human health and the environment. When heated, harmful substances do not evaporate and do not stand out, and, therefore, it is allowed to be used even in rooms with an increased risk of fire. The manufacturer carefully monitors the quality of the raw materials, and also makes high requirements for finished products. In the manufacture, specially developed eco-technologies are used, involving the use of only natural ingredients in the composition.

- Due to the special structure (a combination of long fibers with air layers), GEO Ursa heaters have excellent thermal insulation and noise -absorbing characteristics, despite the small specific gravity. The advantages of products include such properties as fire safety (does not burn and does not support combustion) and bio resistance (not subjected to decay and decomposition, and also does not have conditions for the propagation of insects and rodents).

- Installing is quite easy not even trained people. The material can be laid on any surface, regardless of the degree of curvature. In this case, the plates take the shape of the base and very tightly fit to it. Since the product is quite elastic and elastic, the accuracy when cutting and subsequent fitting is not required, just as there is no need for additional fixation when installed on the frame. You can buy URSA GEO insulation at any large construction store.

Assortment of URSA GEO products:

- Frame P;

- Light;

- Mini;

- Name roof;

- Universal slabs;

- Facade;

- A private house;

- Noise protection,

- Mats: M-11 and M-11f (one of the sides is piled by foil); M-15; M-25 and M-25F (one of the sides is pasted with foil);

- Plates: P-15; P-20; P-30; P-35; P-45; P-60.

The price of URSA insulation depends on the density of the product and may vary from 400 rubles. up to 1,500 rubles. For packaging.

- This is the thermal insulation material of the new generation, its main feature is that 95% of its composition is completely natural ingredients that have undergone quality control. The product complies with international sanitary standards and belongs to the category of eco -materials. According to the recipe, the use of formaldehyde or phenol, as well as any secondary raw materials and plant substances, is not allowed.

- The product has amazing softness, due to the presence of the finest fibers (compared in texture with wool or cotton). Since acrylic is used as connecting components, the products are considered as safe as possible for humans, and is recommended for use in medical-preventive, school and preschool institutions. When working with the insulation, there is no dust and there is no smell. In addition, the color of the material is also surprising, despite the absence of any dyes and bleach. This can be achieved due to the fact that the quartz sand during melting has a white shade, and transparent acrylic substances do not affect the shade of finished products.

- An important advantage of Pureone is that this material has increased elasticity, flexibility and elasticity. This allows not only to more effectively absorb sound waves, but also reliably install the insulation in any structure without the need for additional fixation.

Pureone product range:

- 34pn (plates: 125 cm x 60 cm);

- 37RN (roll: 120 cm x 10 m);

- 35qn (roll: 120 cm x 390 cm).

- This type of product was designed specifically for use at home, but at the same time, the material is fully consistent with the quality standards of professional construction. The peculiarity of the plates is that they have small size and increased rigidity (in this case, flexibility and elasticity remain at the proper level), this allows you to easily install independent forces.

- The insulation has the maximum indicator of thermal conductivity and sound insulation, and also has excellent moisture resistance. To increase the hydrophobizing properties, the product during production is treated with special water -repellent compounds, due to which, when drops of water gets to the surface, they simply roll from it, and do not penetrate inside.

- Terra thermal insulation is a non -combustible material that is ideal for insulation of wooden buildings. In addition, due to the use of only natural components in the production of only natural components, the product is absolutely not harmful to humans and the surrounding nature, that is, it is environmentally friendly and is able to maintain an amazing microclimate of houses erected from wood.

Assortment of URSA Terra products:

- 34 pn (plates);

- 34 RN (technical mat for insulating pipelines and ducts).

Technical characteristics of URSA insulation from EPS

Thermal insulation based on extruded polystyrene foam is characterized by high strength and wear resistance. These products are excellently opposed to moisture and do not absorb it from the air, due to which they are recommended for use in all parts of the house (roof, foundation, basement, facade, floors and so on), as well as during the construction of objects that have contact with groundwater, For example, roads.

- Specific thermal conductivity.This indicator is in the range of 0.032-0.048 W/MK, the material perfectly supports the necessary temperature regime of almost any rooms, and, in addition, does not reduce thermal insulating characteristics even in conditions of high humidity and with direct contact with water.

- The temperature mode of application.It is recommended to use the insulation at temperatures from -50 to +75 degrees. At the same time, products are quite resistant to freezing, more than 500 freezing/defrosting cycles are allowed. It is also possible to use thermal insulation in buildings where a change in temperature regime is quite frequent.

- Strength qualities.Plates and mats are capable of throughout the operational period (that is, more than 50 years) to withstand the load up to 175 kPa, as well as short -term pressure up to 500 kPa. Excellent strength on the bend allows installation even on unprepared bases, for example, on a sand pillow.

- Safety.EPS -based products are completely harmless to humans, since freons and other harmful elements are not used in production. In addition, thanks to the addition of antipyrene, the insulation refers to non -combustible materials, that is, when exposed to fire, these substances create a barrier on the surface that prevents oxygen access, thereby stopping the spread of the flame. It is worth noting the fact that thermal insulation can be used in structures that are close to open ground or vegetation and at the same time completely maintain their physical properties.

Line of materials based on EPS

Ursa XPS

- In this category of goods, only products of the XPS URSA are produced, the material is universal for use, but is most often used in such designs as, for example, runways, railway embankments, underground parts of buildings, plastered facades, soil floors, and so on. That is, it is an ideal heat insulator for use in extreme operating conditions; high humidity or heavy loads are not afraid of it.

- Such materials as concrete (including aerated concrete), metal, brick and plastic can act as insulated surfaces. Products are resistant to a number of chemicals: alkalis, acids, lime, alcohol, oils, fats, phenol, bitumen and others. However, it should be borne in mind that such drugs, which include gasoline, tar, formic acid or hydrocarbons, are not recommended as border materials.

Assortment of URSA XPS products:

- N-V (the strongest material, withstands the load up to 50 t/m2, is available in the form of plates 60x125 cm).

- N-III (has two varieties: N-III-L and N-III-I, the differences are in the form of an edge, which can be stepped or straight);

- N-III-G4 (thickness varies from 3 to 10 cm, parameters 60 x 125 cm);

The main advantages of thermal insulation of Ursa

The insulation produced by URSA can be called a unique option, because it has a huge number of advantages that allow us to say that products are a universal option for any construction. So, what are the advantages of the material.

- Excellent thermal insulation ability.

- High environmental friendliness.

- Increased noise protection.

- Long operational period (more than 50 years).

- Resistance to temperature fluctuations, as well as low and high temperatures.

- Practicality and versatility (wide area of \u200b\u200bapplication).

- Non -combustible material.

- High flexibility, elasticity and elasticity.

- Resistance to high loads.

- Easy installation.

- Available cost.

- Small specific gravity.

- Excellent vaporopods.

- Bio -resistance (that is, rodents and insects do not start in it).

- Does not rot and do not mold.

Of course, it is important to identify negative properties, because they are not in large quantities, they are present. So, for example, mineral isolation is susceptible to an alkaline environment, in addition, fiberglass when cutting the insulation can cause small troubles, therefore it is recommended to work with products in protective clothes and gloves, which is not always comfortable. But in any case, customer reviews about Ursa insulation are positive.

The scope of URSA insulation

Ursa products are universal products that have a fairly wide area of \u200b\u200bapplication, due to a rich assortment series.

Most often, the insulation is used for the device:

- roofs (flat and pitched);

- walls (both from the outer and from the inside, as well as as a gasket for the middle layer);

- inter -story ceilings (including basement and attic);

- partitions;

- floor structures;

- foundation;

- heating pipes;

- railway embankments;

- automobile highways;

- runways;

- loggias and balconies;

- bath or sauna.

Installation of thermal insulation of Urs

Even a person is capable of laying heat -insulating plates or mats without special construction. Since it is enough to observe several simple rules, and the work will be done efficiently and efficiently.

- First of all, it is important to properly transport the material and its storage. So, products from atmospheric precipitation and mechanical damage should be protected. That is, by laying the insulation for transportation to try not to squeeze it and not to place it too tightly, since additional compression often leads to the fact that in the future the sheet simply does not turn out as it should, which means that it can lose its basic functions. With prolonged storage, it is important to leave the factory packaging, and also monitor the fact that the plates are laid horizontally, and the rolls are left vertically (you can install up to three rows on each other).

- They begin to unpack products immediately before use. Before starting installation, rolls should be allowed to lay down in a detailed form (roll mats for the entire length) for 10 minutes. Plates can be used immediately after unpacking. Often the manufacturer puts the material in two layers, if there is no need for such a thickness of the product, then you can simply divide the heat insulator into a nominal thickness.

- When starting work, it is necessary to prepare, that is, it is recommended to put on protective clothes, gloves and construction glasses, these measures will prevent dust from entering open areas of the body. Cut the material on a solid object with a sharp knife or a special saw.

- Mineral -based slabs and rolons are laid tightly to each other and pressed to the base. Also, in cases of placement of material in two or more layers, the joints of the previous rows should be overlap, this will make thermal insulation as productive as possible. With the frame installation of the product, the products should be several centimeters larger than the design, then they will be tightly held without the need for additional fixation. By mounting a heater from EPS it is better to use special adhesive compounds (based on polyurethane or cement).

In principle, installation is quite simple, most importantly, to correctly prepare the base, since these products are installed only on the surface (for example, boards or plywood). At the final stage, the room is cleaned. To do this, it is often recommended to spray the space with water to reduce dust level. After which it is necessary to clean the construction vacuum cleaner.

sanny-pussy Your Ursa

sanny-pussy Your Ursa