When choosing wallpapers, many people act according to the template to buy paper wallpaper with small ...

|

|

The correct choice of insulation will reduce the heat loss of the insulated building and extend its term ... |

Ceramic tiles for wood are one of the most convenient materials for ... |

Polyurethane foam insulation: characteristics, pros, cons

Poliuretan foam is in great demand in the building materials market. It is an excellent insulation for various kinds of designs. We will talk about the features of application, advantages and disadvantages of polyurethane foam.

Table of contents:

- Poliuretan Poliuretan - General information and manufacturing technology

- Polyurethane insulation reviews and methods

- Polyurethane foam insulation: advantages and disadvantages

- Polyurethane foam characteristics of the technical composition

- Technology of thermal insulation by polyurethane foam

Poliuretan Poliuretan - General information and manufacturing technology

Poliuretan foam has the appearance of foamed plastic material with a homogeneous structure in the form of inclusions from air bubbles. It is they who are the main part of it. Poliuretan foam is characterized by the lowest thermal conductivity and good moisture -repellent properties.

In addition, this material is considered environmentally friendly and harmless to human health.

There are several types of polyurethane foam according to its structure:

- Hard -type polyurethane foam;

- elastic type;

- integral type.

The first option is of high density, despite its hardness, it has a slight weight. Hard polyurethane is excellent both sound and heat insulator.

The elastic version of polyurethane is similar to foam rubber, although, in comparison with it, more durable and durable. Its use is associated with the manufacture of furniture, due to harmlessness, this material is widely used in the medical industry.

The integral version of polyurethane foam is distinguished by a monolithic structure and the most dense consistency. Its use is associated with the automotive industry.

The first scientist who discovered polyurethane was Bayer Otto. He planned to invent a material that would completely replace the rubber.

In the modern construction industry, polyurethane foam is an indispensable thermal insulation material. This is due to the ease of its weight, moisture resistance, a minimum coefficient of thermal conductivity.

There is an option to spray polyurethane foam to the surface, thus it is possible to obtain a seamless structure with excellent thermal insulation characteristics.

It is these characteristics that make polyurethane foam popular as a heat insulator. The hard version of polyurethane foam is designed for the manufacture of heat -insulating panels that differ in ease of installation and stability in front of heat loss. A fairly popular option is the use of sandwich panels, as a thermal insulation layer in which polyurethane foam is used. With their help, in the shortest possible time, various kinds of premises and buildings are erected. In addition, clinker tiles - also consists of a thermal insulation layer, for the manufacture of which are used polyurethane foam and a decorative outer layer, from ceramics.

The manufacture of polyurethane foam is based on mixing various kinds of components, such as isocyanate and polyol. During this procedure, the material is foamed and increased in volume. Next, its hardening occurs.

During the manufacture of polyurethane foam, you should adhere to a certain technology, which involves holding a certain air temperature when mixing components. In addition, all components should be strokes qualitatively.

If the air temperature is low enough, then polyurethane foam will require a large amount of raw materials for its production, the amount of marriage, after the completion of the manufacturing process, will increase several times than at an optimum temperature.

High -quality mixing of all components allows you to obtain polyurethane foam a homogeneous structure in which there are no air cavities and seals.

Polyurethane insulation reviews and methods

There are two ways to make polyurethane foam:

- with the help of spraying;

- filling.

The first option is characterized by more favorable conditions, since it does not require additional installation of building structures. Popenia of polyurethane foam helps thermal insulation of residential, public and industrial premises, pipelines, tanks, etc.

Polyuurean foam easily falls on various surfaces, even oily. Due to the fact that the thermal conductivity of this material is quite low, it is applied with a small layer and can save on the amount of material. In addition, the fusion method allows you to get a holistic seamless structure that prevents heat passing.

To carry out laying polyurethane foam, this method is used by special equipment that mixes ready -made components with each other and supplies them under pressure on the surface necessary for insulation.

Pouring polyurethane foam is mixing the components with each other and their supply to the surface without air exposure. In this case, the consumption of the material is increasing. Using this method, shells installed on pipelines requiring thermal insulation are made. Also, using this equipment, it is possible to make polyurethane plates or sandwich panels. The material is poured in a special kind of form in which it freezes and acquires the desired size.

Also, polyurethane products are made, which decorate the interior or exterior. In order to save on the installation of the insulation, pour polyurethane foam into the space that is located between the walls. If you compare a brick with polyureton foam, then a layer of insulation, 1 cm thick, equal to brickwork, the thickness of which is 25 cm.

Therefore, the use of polyurethane foam during the construction of the house allows you to get a building, with excellent thermal insulation characteristics for the affordable cost. Keep in mind that when using the method of pouring polyurethane foam, in the process of manufacturing various kinds of products, a special kind of lubricant should be used, which are applied to the surface of the form, in order to avoid adhesion of the material with its surface.

Polyurethane foam insulation: advantages and disadvantages

On the insulation of the walls with polyurethane foam, we will single out the following advantages:

1. A high level of adhesion with almost any types of surfaces, with oil, wooden, glass, brick, metal. In addition, the shape and curvature of the surface does not affect the quality of insulation. The surface before applying polyurethane foam does not need to be prepared or additional processing of various kinds.

2. The minimum consumption of the material is ensured by the use of the spraying method. In addition, the installation of polyurethane foam is quite simple and is performed directly on the construction site.

3. Polyurethane foam is quite light material, so it does not load the overall design of the building, especially relevant for thermal insulation of roofs.

4. When using polyurethane foam as a heater for walls, they, in addition to low thermal conductivity, acquire additional strength.

5. Poliuretan foam is stable before changes in the temperature regime, the temperature interval for it is from -150 to +150 degrees.

6. The service life of polyurethane foam is at least 20 years.

7. The procedure for applying insulation involves obtaining a homogeneous mass in which there are no seams or cold bridges.

8. For the installation of polyurethane foam as a heater, it is not required to install fasteners or special structures.

Despite this, polyurethane foam has certain disadvantages, among which they highlight:

1. The rigid type of polyurethane foam is characterized by a rather low vapor permeability, which negatively affects ensuring a comfortable atmosphere in the room. If we apply polyurethane foam to the attic, then its walls will be subject to dampness, as well as the spread of mold and fungus.

2. Ultraviolet radiation, which falls on the coating of polyurethane foam, worsens its thermal insulation characteristics.

3. Thermal insulation with polyuretone foam using the spraying method implies the presence of a low level of fire safety. Since the coating acquires increased combustibility.

4. The installation of foam in the space between the walls, if they are made of fragile materials, leads to deformation, since polyurethane foam expands and creates a certain pressure.

Polyurethane foam characteristics of the technical composition

It is the hard type of polyurethane foam that is used in the construction industry. Since it is characterized by good heat -insulating characteristics, steamability, water resistance, stability before corrosion, aggressive environment and radiation. In addition, it is characterized by high strength, stability before changing the temperature regime and various kinds of other external influences. We offer to get acquainted with the technical features of the insulation called polyurethane foam:

1. The properties of thermal conductivity.

This factor depends on the size and number of empty cells that are in the polyurethane foam. Although, if we compare this material with polystyrene, mineral wool or other insulation, then the polyurethane foam wins.

2. Sound absorption.

This property depends primarily on such parameters as elasticity, vapor permeability, the thickness of isolation, etc. In polyurethane foam, the level of sound insulation is determined by its density and rigidity, the higher it, the better the material does not miss sounds.

3. Stability before chemical compositions.

Polyiuretan foam has higher stability before an aggressive environment than, for example, polystyrene. It is perfectly opposed to gasoline, various kinds of oils, alcohol, acids and plasticizers.

When applying polyurethane foam to the steel surface, protection is formed in the form of two films that are inside and outside the material. They do not allow moisture and other chemicals on the steel surface, thereby preventing its corrosion.

4. Moisture absorption level.

This material has a very low level of moisture absorption. This factor is affected by the number of different components that make up the polyurethane foam. The denser the structure of the insulation, the less moisture it is able to pass or absorb through itself. The presence of castor oil in the material of the material increases its moisture resistance several times.

5. Fire safety.

It has a fairly low combustibility. To increase fire resistance in the process of preparing the material, special additives are introduced into its composition or chemical components are changed. To perform the second option, a considerable amount of money will be required, so the first option is more popular, according to which fillers are added to the ingredients for the manufacture of polyurethane foam in the form of phosphorus or halogen compounds.

6. Characterization of the density of the material.

This property is completely dependent on the technology of the preparation and application of polyurethane foam to the surface. The choice of density depends on the specific conditions of the use of this substance. For example, material with low density is great for the manufacture of furniture, the average density of polyurethane foam allows you to insulate buildings, and an extremely dense substance is used to finish the cabin in cars.

7. Duration of operation.

The minimum period of use of this material, subject to the technology of its manufacture, application and operation, is twenty years.

8. Polyurethane foam is not harmful to health or environmental safety.

After 15 seconds, after applying the material to the surface and hardening, it does not cause any harm to a person. When the material is heated to a temperature of more than 450 degrees, it begins to release carbon dioxide and carbon monoxide.

Technology of thermal insulation by polyurethane foam

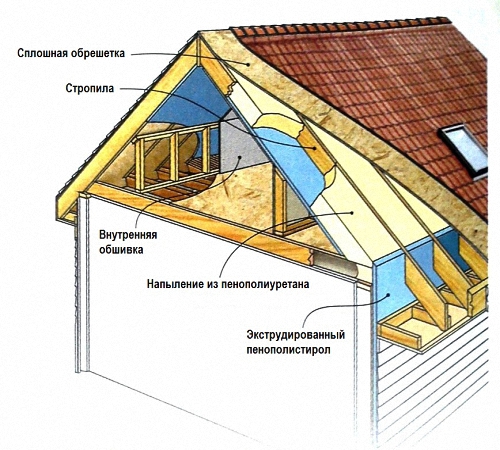

In the process of insulation of various surfaces, polyurethane foam is used hard, semi -rigid type. The first option has a closed structure and is relevant when warming hard structures, concrete or brick composition. The second version of this insulation is used in the implementation of thermal insulation of frame houses, drywall structures, plywood or wooden buildings.

A heater, which has a closed structure, is almost zero moisture absorption and excellent soundproofing characteristics.

The inner part of the room is insulated using spraying, since as a result of this the dew point begins to form and the walls are freezed. But using the insulation of the external sections of the building, it is possible to achieve not only good thermal insulation, but it is also not required to install steam and sound insulation. In addition, the useful area of \u200b\u200bthe premises remains the same, and the walls receive excellent protection against external influences.

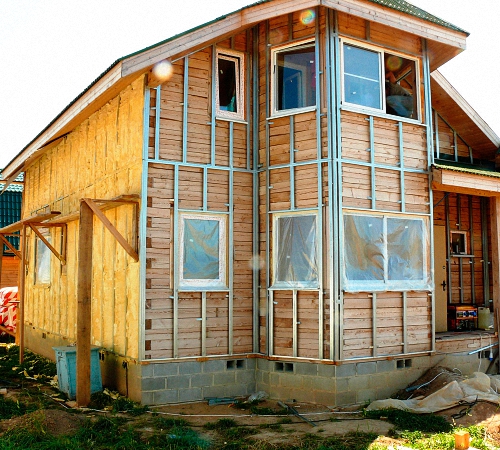

Brick or frame walls are insulated with a device that supplies material under pressure. For several tens of seconds, polyurethane foam from liquid foam goes into a solid state. After polymerization of the foam, excess is cut off from it and plaster is applied to the surface or plasterboard is installed.

With the external application of foam, vinyl siding or facing brick is installed. It is possible to install hinged panels or even paints on a silicate or acrylic base.

The best protection for polyurethane foam is a polymochevin, which is able to last more than 45 years as an external decoration, although its cost is too high.

To ensure good adhesion of foam and coating, it should first be cleaned of dust. After applying the insulation, it is covered with a primer.

The option of using finished polyurethane foam plates is possible. They differ in the ratio with density, thickness and size. Since the purchase of expensive equipment for applying polyurethane foam is not always relevant, this option becomes more acceptable.

The slabs should be mounted on a dry, pre -leveled surface, which was previously cleared of dust. The quality of the insulation depends on the evenness of the wall. To fix the plates, adhesive mastic is used; for additional fastening, special dowels have a wide hat are used.

To eliminate not docks or cracks, installation foam has a similar composition. Therefore, the surface becomes sealed and monolithic.