After the manufacture and finish of the roof, the process of its skin follows. This procedure ...

|

|

No matter how hard the masters try to perfectly install plumbing close to the wall, all the same ... |

The rack ceiling is a suspended structure with an attractive design ... |

Penofol insulation: step -by -step instructions for installation

A multifunctional material is represented on the construction market - a foam, which with a minimum thickness provides almost 100% result. It is used for heat and sound insulation of buildings of any type. It can act as an additional and independent layer.

Content:

Penophol insulation

The assortment of the foam allows you to use it in individual houses, civilians and industrial buildings:

- insulation of walls, floors, ceilings, attic and attic rooms;

- insulation of pipes in water and heating systems;

- insulation of equipment in various fields of industry, including rural, medical and food production;

- ventilation and air conditioning systems;

- insulation of various types of installations used to transport cold and hot foods;

- rooms with high temperature conditions (drying chambers, baths, saunas, etc.);

- heat and sound insulation of cars of passenger and freight transport;

- this universal material in warm floor systems is widely used.

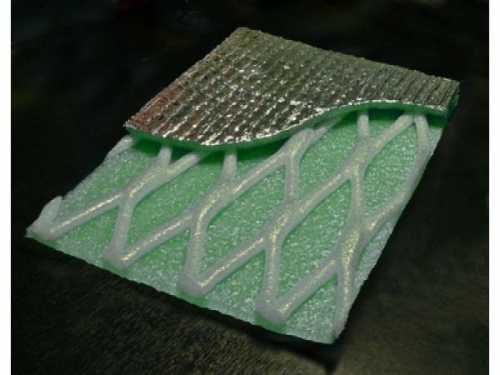

Penophol photo

Penofol insulation foil

The combined material consists of the main layer, that is, porous polyethylene with one or double -sided coating of a metal sheet (foil). Its uniqueness lies in the simultaneous performance of several functions at once: convection and heat reflection. Thus, with a small thickness of the foam, it is possible to achieve amazing heat and sound insulation. The material is available in rolls. Sheets can have a thickness of 3 to 10 mm.

The comparative table presents various types of building materials, using which you can achieve the same result. Penophol of the type in a thickness of 4 mm is equivalent:

| name | Thickness (mm) |

| Brick | 672 |

| Silicated brick | 840 |

| Gas -Penioboton | 348 |

| Mineral wate | 67 |

| Foam polystyrene | 46 |

Advantages

- Environmental purity. Raw materials for production are polyethylene and foil, which have been successfully used in food and medical industries for many decades.

- The thin layer of material guarantees high indicators for thermal resistance. A foam sheet of 4 mm thick is equal to the wall masonry of 2.5 bricks;

- High vapor permeability provides free release of excess moisture. The absorption of the material is zero, so its use is possible in rooms with a high level of humidity. Also, foil polyethylene foam is used for external work.

- The material is characterized by excellent soundproofing properties. It will protect the structure from acoustic and structural noise.

- The light weight of the sheets provides operational installation. Thanks to elasticity, the material lies perfectly on any surface. Physics can be carried out by an ordinary kitchen knife. Fasteners are carried out through self -adhesive aluminum ribbons, furniture stapler.

- Non -combustibility. Fire-technical characteristics say that the presented material refers to a low-combat and difficult to fill groups (G1 and, respectively, B1). With prolonged exposure to open fire, sheets can flicker slightly (smoke -forming abilities D2).

- Convenience in storage and transportation. Light and flexible canvases turn into compact rolls, which fit even in the trunk of a car.

Flaws

- The softness of foamed polyethylene favorably affects the installation, but negatively manifests itself with further decoration of the building or premises. The surface is not intended for plastering or gluing wallpaper.

- Despite the high physical and technical characteristics of the material, in most cases it is used as an additional layer. To achieve an effective thermal insulation result, it is recommended to use in combination with other types of insulation.

Penophol video

Penophol Application

The manufacturer presents several modifications, the letter designation of which reports its features.

| type of | Thickness (mm) | Length (mm) | Width (mm) | characteristics | the scope of application |

| BUT | 3.4.5, 8 and 10 | With a thickness of up to 5 mm 3000 mm; 8 and 10 mm 1500 mm | 1200 | foamed polyethylene with one foil side | It is mainly used for insulation of walls, attics and attic together with other types of insulation. This material is widely used to isolate engineering systems |

| AT | 3.4.5, 8 and 10 | With a thickness of up to 5 mm 3000 mm; 8 and 10 mm 1500 mm | 1200 | The basis of foamed polyethylene with double -sided foil | Effective as an independent insulation for inter -story floors and internal walls, partitions |

| FROM | 3.4.5, 8 and 10 | 600 | One side of polyethylene foam is covered with aluminum foil, the other by a self -adhesive layer. Installation is carried out without the use of additional means of fasteners | Used for insulation of complex structures, optimal for hard -to -reach places | |

| Alp | 3 | 3000 mm | 600 | The base is covered with foil on one side. The foil side is laminated with plastic wrap | This product provides reliable protection against corrosion processes. Perfect for use in systems warm floor |

Today, products and other modifications are produced, for example, with a reinforced base (glasshold) or additional perforation, which are designed for external insulation of building structures.

How to warm with foam

- It is quite simple to mount the canvases, the fasteners to the surface are carried out by means of stapler's brackets or adhesive compounds. The sheets have a junction of the VSTOK, however, it is allowed to lay over up to 10 cm. The foil side should be facing the room, house, pipes, etc.

- Particular attention should be paid to insulating the wiring, since aluminum is a good conductor of electricity. Plastic channels or corrugated pipes can be used here.

- The basic rule, which must be observed without fail, is the presence of a ventilation gap of 1.5-2 cm on both sides of the material. This is due to the fact that the polyethylene base is absolutely waterproof, therefore, inevitably arising moisture during the operation of the structure, will accumulate and moisturize other structural elements.

- Installation joints or random cuts of paintings are glued with self -adhesive aluminum tape (Las or LAS). Installation adhesive tape provides complete steam and waterproofing of the system.

Wall insulation with foam from the inside of the room

Internal insulation of the walls will prevent moisture, and therefore the development of mold and fungus. The work is carried out in the following order.

- The rail with a thickness of 1.5-2 cm is attached to the surface in the vertical position, this characteristic will provide the required ventilation gap. The step between the bars should be 600 mm. Since the width of the canvas is 1200 mm, this indicator is optimal for the installation of insulation.

- Laying is performed by the foil side inside the room. The edges should be located in the middle of the rail. The next sheet is the junction of the previous one. The optimal fastener is a construction or furniture stapler, you can use small nails.

- The cutting of paintings in length is carried out by means of a ruler and a sharp knife or blade.

- All connecting seams are glued with special tape, which will provide complete sealing between the canvases.

- The next step is re -installation of the rails. Their location is selected depending on the characteristics of subsequent finishing materials. A wooden frame can serve as the basis for fastening panels made of plastic or wood, as well as drywall sheets that put up and then painted or pasted with wallpaper.

Installation of foam outside the structure

Experts say that the most effective way of insulation is the installation of thermal insulation material from the outside. The perforated modification of the foam promotes the free removal of steam and moisture emanating from the building. In addition, the material protects the walls from wind and atmospheric precipitation, provides a high level of sound insulation. The considerable advantage of the external installation of the insulation can include the savings of the useful area of \u200b\u200bthe room.

- Warming is recommended in dry, warm weather. The surface is cleaned of previous coatings, dust and dirt. Then it is subjected to antiseptic treatment. Particular attention should be paid to the corners and lower parts of the walls, it is they who are more prone to freezing.

- As with internal insulation on the surface, rails are mounted. Fasteners are selected depending on the material of the walls.

- The canvases are spread out the joint. The mount is carried out by a stapler. The seams between the sheets, as well as the joints of their upper and lower parts, are glued to the walls with mounting aluminum tape.

- Next, the outer frame is equipped, which is faced with profiled sheets, vinyl siding and other materials. If a brick acts as a cladding, then there is no need for a second frame. In this case, the masonry is built at a distance of 30-40 mm from the load-bearing walls with the necessary ligament, taking into account the features and nature of the constructed structure.

Penophol of cement floor with a foam

- Material of brand A can be used as a substrate for parquet, laminate, linoleum. It will show high rates for heat and waterproofing, as well as noise absorption.

- For insulation of concrete floors, the screed with a solution with the addition of expanded clay is first performed. However, it is possible to avoid dirty and time-consuming work if this layer is replaced with foam with a thickness of 5-10 cm, on top of which the canvases are covered with a foil side.

- The edges should go to all walls of 10 cm. The cloths themselves are laid without overflow. The connecting seams are glued with aluminum tape.

- For the ventilation gap between the insulation and finishing material, slats or lags are filled. Wooden elements are treated with antiseptics to prevent premature decay.

- The indentation of 1-2 cm is made from the wall and the rails are mounted along the entire length of the room with a step of 40 cm. The horizontality is checked by the construction level or laser, if necessary, adjustment is carried out by placing the chip.

- The edges of the insulation that interviews on the walls are neatly cut off.

- Sheets of plywood (12 mm), fiberboard or chipboard are laid on top of the frame. Self-tapping screws are screwed every 15-20 cm. Black floor is covered with any facing material.

Installation of foam in the system warm floor

- The presented material provides not only hydro- and sound insulation, but also guarantees excellent heat transfer due to the reflective layer of foil.

- The canvases of the brand A or C are spread out the top on the basis of the junction of the VSTOK with a mandatory setup on the walls (10 cm each). The joints of the material and random cuts are glued with mounting tape (LAS).

- Next, laying heating elements is performed. Between them are bars, which will serve as the basis for laying parquet, laminate or other piece products.

- In the case when the heating system is poured with a sand-cement screed (under ceramic tiles), the modification of the alp foam is used. This type of material does not respond to an unfavorable environment.

- Laying is carried out with an interchange on the walls and joints, the seams are glued without fail.

- After the installation of heating elements, the system performance is tested. Then the reinforcing mesh is lined and the concrete solution is poured. When the screed dries, the protruding edges of the foam are cut.

The physical and technical characteristics of this material makes it possible to use it for insulation and simultaneous protection against cold, damp and noise. At the same time, a small thickness of the foam allows us to rationally use the internal and external space of buildings and other structures without loss of functional properties.