The construction of the visor above the porch opens a lot of advantages in front of the owner of the house ...

|

|

The windows are a kind of adapter between the outside world and your house. Hearing ... |

There is a common problem in regions with snow winters ... |

Insulation of the attic: the choice of material and installation

There are many options for insulation used in the process of insulation of the attic of the house. The choice of a particular method of insulation depends on the individual characteristics of the building and the material capabilities of its owners. About how and how to insulate the attic we will consider further.

Table of contents:

- Insulation of the attic mine - technology and advantages

- Ways to insulate the attic by expanded clay

- The procedure for insulation of the attic foam

- DIY attic insulation with sawdust

Insulation of the attic mine - technology and advantages

Mineral wool is a fairly popular material used in the process of insulation of the attic. The main advantage of this insulation is the simplicity and ease of laying it. It should also be noted:

- excellent thermal insulation characteristics;

- ensuring coolness in the summer and maintaining heat in winter;

- the possibility of use in areas of different complexity;

- environmental Safety;

- resistance to microorganisms and rodents;

- Great sound absorption and thermal insulation.

There are two main types of mineral wool:

- basaltic;

- fiberglass.

The first option implies the presence of high properties of resistance before moisture and acids, and the second is characterized by higher elasticity, fire resistance.

Please note that the use of mineral wool during insulation of the attic needs to comply with certain rules and norms of working with the material. First of all, it is necessary to use protective glasses and a mask, to protect your hands, it is necessary to have rubber gloves.

To insulate the attic overlap with mineral wool, the presence of:

- boards or plywood;

- vapor barrier materials;

- the required amount of insulation;

- waterproofing film;

- Scotter or special tape.

From the tools, you need to prepare:

- roulette;

- stationery knife;

- stapler;

- putty knife.

If the attic ceiling is made of reinforced concrete plates on which the supporting beams are located, then thermal insulation material will be located directly between them. Otherwise, the laying of mineral wool is carried out right on the floor. In order for mineral wool to serve for a long time and does not lose its operational characteristics, high -quality vapor barrier should be provided.

If this is not done, then moisture will fall into the attic from the premises, and therefore will absorb into the mineral wool, it will become heavier and eventually lose the characteristics of thermal insulation purpose.

Therefore, before laying mineral wool to the surface of the attic floor, vapor barrier should be laid. First, conduct calculations for determining the amount of mineral wool, which will be required in the process of performing work. To calculate the thickness of the laying of mineral wool, such factors as:

- climate of this region;

- the material from which the floor is made and the walls of the building;

- finishing roofing material and its properties, etc.

Keep in mind that in the process of buying mineral wool you should make sure that the packaging is tight in which it is located, since this type of material is highly sensitive to moisture.

Instructions for insulation of the attic using mineral wool:

1. On the surface of wooden lags, plywood or premixed base should be laid. Thus, it will be possible to freely move on the surface of the attic.

2. Cover the vapor barrier material, so that it goes beyond the walls by 20 cm, and over 10-15 cm is overlapping. To connect the paintings, use tape.

3. When not using the attic as an attic room, it is necessary to equip the ventilation of the undercarbon space, the devices in the form of ventilation gutters should be attached to the roof crate.

4. Next, install mineral wool on the surface. It is recommended to use its roll shape. To cut the material, use a regular stationery knife. Roll the next strip opposite to the previous one. Take care of the tight attachment of the fibers so that in no case, there is no gap between them.

5. In the presence of cracks, place trimming the insulation in them. In the presence of lamps on the ceiling, use special covers to close them. Mineral wool should not be deformed in the process of working with it.

6. Put a vapor -permeable coating in the form of a superdiffusion membrane on top of the cotton, which will prevent the insulation from the mineral wool surface.

7. Keep in mind that the membrane is distinguished by a one -sided principle of operation, so the main thing is not to confuse which side should be laid.

8. In the presence of waterproofing on the roof of the building, there is no need to lay a membrane.

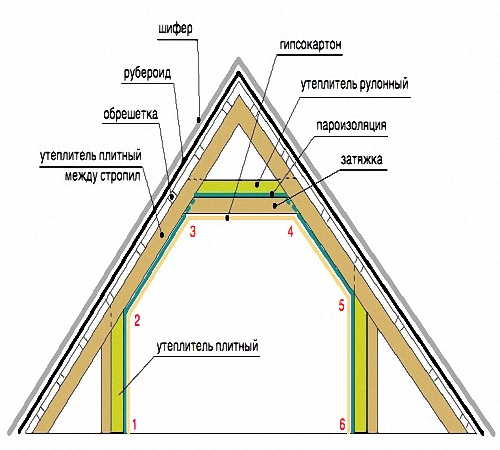

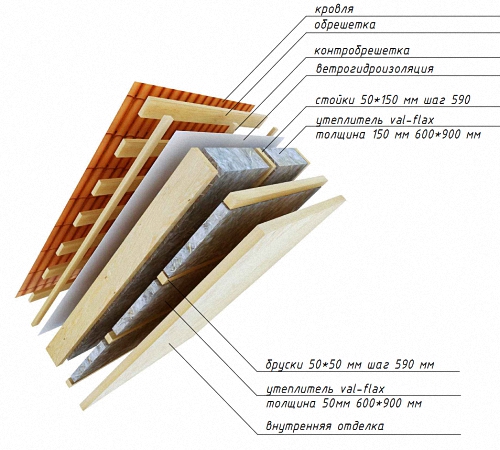

In the process of insulation of the attic in a private house, there is a need to lay mineral wool on the surface of the slopes. The arrangement of a warm ventilated roof allows you to provide additional protection of the attic from thermal losses. Skut insulation is similar to the formation of a multilayer pie, which is installed both on the outer and in the inside. For insulation of the attic or attic, mineral wool, we recommend performing the following actions:

- ensure vapor barrier - protect mineral wool from moisture, which is formed in the room;

- installation of insulation, that is, mineral wool;

- ensuring waterproofing - protection against moisture in the outer part of the roof;

- The control crate helps to form a ventilation space inside which the air will circulate;

- Installation of roofing.

Ways to insulate the attic by expanded clay

It is better to insulate expanded clay at the stage of construction of the whole house, however, a variant of insulation of a ready -made attic is possible. To complete the work, the availability of:

- diverse expanded clay;

- vapor barrier material;

- material. from which the fence will be formed;

- clay;

- painting tape;

- cement and sand;

- The material from which the floor will be laid: plywood, boards or laminate.

To warm the attic using expanded clay, special work skills or special equipment are not needed. Even one person is able to carry out all the work. Keep in mind that the work will require precisely a diverse expanded clay, since it will help to form a layer that is tightly adjacent to each other.

Work should start with the construction of a fence, inside which expanded clay will be located. To determine its height, you need to take into account factors such as:

- climate of a particular region;

- the total number of heat loss of the building;

- The ratio of expanded clay with thermal losses.

To calculate thermal losses of the attic, the heat loss of the building should be determined based on the total area of \u200b\u200bits ceiling. To conduct calculations, contact professionals or conduct them yourself. Keep in mind that the total mass of the structure should not load the floor too much.

Since the overlap needs additional protection against moisture, a vapor barrier is laid before the backfill of expense. Installation of vapor barrier is a mandatory step, which in no case should be missed. If you do not establish vapor barrier, then expanded clay is filled with moisture and will not perform the functions intended for it.

Properly established vapor barrier not only improves the properties of the insulation, but also positively affects the service life of the entire floor, especially if it is made of wood.

Instructions for the installation of vapor barrier before laying expanded clay:

1. The material must be cut into parts, each of which is 100 mm more than the distance between the beams.

2. The laying of the material is carried out in strips, the minimum value of the overflow between which is 12 cm.

3. For gluing roofing material at the joints, it is lubricated using bitumen mastic.

4. If it is planned to use isospan, then a special tape is used to glue it.

5. If a chimney is located in the attic, then it is also wrapped using vapor barrier.

6. Keep in mind that the height of the streak of vapor barrier should be 20 cm higher, backfill of expanded clay.

7. Fix vapor barrier on the wall with tape or stapler.

At the next stage, well -cooled clay is laid on the surface. To do this, use the spatula, make sure that the vapor barrier remains integral.

Pour the expanded clay gradually, try to ensure that the layer of kerasmit is quite dense. The optimal backfill thickness is from 10 to 16 cm. Expanded clay should not be located higher, previously constructed fence.

Next follows the process of laying the screed. It should not be neglected, so the screed helps to improve the thermal insulation characteristics of expanded clay. After completely drying the screed on the floor, a black plywood or boards coating is laid. Next, finishing the floor is made.

The procedure for insulation of the attic foam

Among the materials of insulation of the attic, foam, perhaps the most economical option. Among the advantages of using foam, it should be noted its lightness, good heat -insulating characteristics, cheapness and simplicity of laying.

Despite this, this material has certain advantages. He is unstable to mold and fungus, he does not have fire safety, as he quickly ignites.

The technology of insulation of the attic using foam is as follows:

1. Measure the total area of \u200b\u200bthe attic floor that needs insulation. Add 10% to it to eliminate surface defects, when calculating the amount of foam.

2. In addition to foam, the presence of waterproofing and wooden rails will be required, from which the crate will be built.

3. Remove the old filling from the surface of the roof. Lay waterproofing. To fix it, use a special tape.

4. Build the base of the crate. For these purposes, a beam is used, the cross section of which is 100x100 mm.

5. The stacking step of the beam is compared with the width of the foam. Install the foam.

6. Fix vapor barrier on its surface. Since the foam is exposed to moisture, and if this is not done, it will lose its properties.

7. Next, sheathe the surface with drywall, plywood or plastic -based panels.

Keep in mind that along the entire perimeter of the attic should be equipped with a thermal insulation circuit. The entire rafter system is carefully waterproof and impregnated with antiseptic compounds.

The option of external insulation of the attic is possible using foam. In this case, the presence of a denser material with the best technical characteristics will be required. Fix the foam on the surface with glue and special screws.

DIY attic insulation with sawdust

Among the advantages of insulation of the attic using sawdust we select:

- non -toxicity, hypoallergenicity;

- good thermal insulation indicators;

- cheapness.

In addition, the use of sawdust is especially relevant when warming the cold attic. Since sawdust should be mixed with a binder and applied to the surface, if it is planned to additionally operate the attic, then the black floor should be laid out from above.

The insulation of the attic with sawdust begins with the flooring to the base of Pergamine. Before this, it is recommended to process wooden parts of the ceiling using fireproof impregnations.

Keep in mind that when choosing sawdust, you should give preference to those materials, after the manufacture of which passed at least one year. If the sawdust is wet, then there is a risk of exfoliation. In addition, they should not be affected by mold or fungus.

For applying on the surface, the sawdust is mixed with a cement mixture in a ratio of one to ten. Water is added gradually so that the composition acquires slight humidity.

For 5 buckets of sawdust, you will need to cook about 0.75 buckets of water. In the beginning, dry cement is added to the sawdust and they mix well with it. Next, add water.

Pour this composition to the surface and compact well. Wait for the complete drying out of the composition, it is achieved in the presence of a crunch, in the process of walking along the floor.

Keep in mind that if the sawdust has a fairly small fraction, then the water, for the preparation of the composition, is needed more. Cement is just a connecting substance, so its number should be minimal.

The option of using clay with sawdust as insulation is possible. This composition has the following characteristics:

- ease of manufacture;

- heat resistance;

- Available cost.

Before applying the composition, a plastic film is laid on the floor, for the fixation of which a simple stapler is enough. Before preparing the solution, clay should brew in it previously added water for two days. Next, clay is poured into the concrete mixer and sawdust is added, the mixture is thoroughly mixed.

The thickness of the layer of applying the solution should not exceed 10 cm. Try to thoroughly trim the composition, when the cracks are formed, they are wiped with clay.

Insulation of the attic video: