Modern technologies and building materials allow you to make practical, reliable ...

|

|

In an effort to effectively use the entire affordable area of \u200b\u200bthe country house many ... |

Stretch ceilings are quite durable and reliable coating that serves ... |

Silicone sealant for the bathroom: characteristics, choice, instructions for use

In professional construction and home repairs, you can not do without silicone sealant. The material replaced with traditional bitumen mixtures, home -made mastics and various lamps that are used to glue parts, seal joints and seal various cracks.

Consider the technical and operational properties of the sealant, describe its varieties and features of application, as well as give tips on choosing and applying a silicone insulator.

Content

- Composition and properties of silicone sealant

- The field of use of sealant

- Types of silicone sealants and features of their application

- Overview of the main manufacturers of silicone sealant

- Tips for choosing optimal sealant

- Sea sealing: step -by -step instructions

- Safety precautions when working with sealant

- How to clean the surface from sealant correctly

Composition and properties of silicone sealant

Silicone sealant is a viscous dense mass used to isolate different seams, gluing surfaces and sealing joints. The material retains the moisture resistance of the sealing structure and protects against external negative influences.

The composition of silicone sealant includes the following components:

- the basis of silicone rubber;

- the amplifier gives strength to the material and determines the tixotropic properties (viscosity level);

- an adhesion primer is responsible for the reliability of the clutch of the sealant with the treated surface;

- silicone plasticizer increases the elasticity of the material;

- the vulcanizer transforms the primary pasty form of the sealant into a material resembling plastic rubber.

In addition, some manufacturers add additional components to the sealant, expanding properties and the sphere of application of material:

- the color pigment is added at the production stage and gives the grout of the desired shade;

- fungicides are able to destroy or prevent the appearance of mold and fungi (especially relevant when used in wet rooms);

- mechanical fillers (quartz or glass dust, sand) improve adhesion of materials.

A rather complex composition determined the basic characteristics of silicone sealant:

- The elasticity of the material allows the use of sealant when starting joints, cracks on mobile compounds. When stretching the fiber, sealants are able to lengthen to 900%, so silicone sealants are not afraid of the seam displacement and sharp turns.

- Resistance to temperature fluctuations. The operating temperature range is from -50C to +200C (heat -resistant sealants can be kept up to +300C).

- The material is not susceptible to aggressive effects of external factors.

- High water resistance.

- Resistance to aggressive environments.

- Good adhesion with the vast majority of materials.

- Biological attacks of fungi and mold are not afraid of silicone sealant.

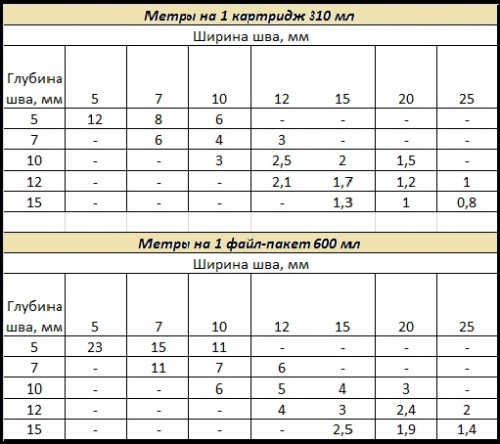

Table. Consumption of silicone sealant

Possessing significant advantages, sealants from silicone are not devoid of disadvantages:

- difficulty in processing wet surfaces;

- not all sealants after application are stained;

- insufficient adhesion with plate of polyethylene, polycarbonate, fluoroplast.

All these shortcomings are devoid of professional silicone sealants, which include organic substances and mechanical fillers.

The field of use of sealant

Silicone sealant is used to perform external and internal construction work.

The range of repair work on the street:

- sealing seams of drain pipes;

- sealing of window frames and joints;

- repair of stone tiles that are exfoliated from the base;

- sealing seams when laying the roof;

- sealing joints of vinyl cladding.

Indoors of the sealants are used when performing:

- sealing the joints of walls, ceiling, floor with drywall structures;

- sealing seams on countertops and window sills made of natural or artificial stone;

- sealing parts subject to high temperature loads.

Silicone sealant for the bathroom is actively used:

- mirror installation;

- installation of plumbing and sealing places of adjoining;

- sealing joints of sewer pipes;

- filling joints when installing a bathroom, shower cabin.

Types of silicone sealants and features of their application

All silicone sealants are divided into two groups:

- One -component- the most common view of everyday life; Sold in tubes, foyle packages. The hardening process occurs when in contact with the air. Complete hardening is achieved only with a thin layer of material 2-15 mm.

- Two -component (silicone compounds) are used in the industrial sphere. The material is solved when in contact with the catalyst, there are no restrictions on the thickness of the plug.

One -component sealant depending on the composition of the vulcanizing substance are divided into two types: acid and neutral.

The characteristics of the sealant of silicone acid type:

- the sealant emits acetic acid, which can provoke the corrosion of copper, zinc, lead, brass and other metals;

- available cost of silicone sealant (you can buy a bottle of 300 ml for $ 2.5-3);

- acid sealants have a mark of A.

Important! Before using silicone sealant, it is advisable to make a sample whether the combined materials react with acid will enter. This is especially true when working with marble and cement surfaces. The composition of such materials contain carbonate, lime and other alkalis that may begin to interact with acetic acid

Neutral sealant It is considered more universal and is suitable for processing different surfaces. Ketoxim or alcohol acts as a vulcanizing substance.

Characteristics of neutral sealants:

- the ability to withstand high temperatures (up to 300C);

- high -temperature sealant is indispensable in the construction of baths and saunas;

- high degree of bacterial protection;

- the relative high cost of neutral sealant of silicone (price for one cartridge for $ 300 ml $ 5-7).

There are sealants of narrow specialization designed to perform specific tasks.

Car They are used in the repair of a car and replacing gaskets. The material protects the details from the effects of water, machine oil and antifreeze, does not flow when applied and is able to withstand the short -term exposure to high temperature.

Important! It is necessary to avoid contact of car sealant with gasoline

Bitumen sealant Suitable for roofing, repairing roofs from slate and tiles, sealing cracks in the basement and foundation, installing the drainage system.

Aquarium sealant Able to withstand a lot of water pressure. It is used to connect and seal joints in terrarium and aquarium structures.

Sanitary sealant Contains a biocide that prevents the development of fungi. Used in the repair of the bathroom.

Overview of the main manufacturers of silicone sealant

In the construction market, silicone sealants are presented in a wide range. Among the manufacturers, we can distinguish companies that have proven themselves from the best side: Makroflex, Ceresit, moment, Tytan and Soudal.

Makroflex The Finnish company with more than 30 years of experience in the production of silicone, acrylic sealants, liquid nails and polyurethane insulating elements. Makroflex products can be used in the most extreme conditions.

The line of sealants of the company includes:

- Sanitary silicone sealant (Makrosil SX101) is a one -component composition with antifungal additives, hardens under the influence of wet air. The cost of the bottle (290 ml) is about $ 3.

- Neutral silicone sealant (Makrosil NX108) Professional one -component material with antiseptic agents is suitable for working with metals, alkaline materials, plastic, ceramics, enamel, glass. The price per tube (290 ml) is about $ 4-5.

- Universal silicone sealant (Makrosil AX104) is suitable for external and internal work, resistant to chemical and atmospheric influences. Price for 290 ml $ 2.5.

International holding Soudal It supplies products in more than 100 countries around the world. The company has its own research center developing innovative technologies for the production of building materials and controlling the quality of products. Soudal has developed a household and professional line of sealing adhesive masses.

Household sealants (sanitary, neutral, universal, high-temperature and silicone for aquariums) persistent to UV radiation and have high mechanical strength. The price of a tube (300 ml) $ 2.8.

The company produces silicones of narrow orientation for glazing, marble, aquariums, mirrors, high -temperature silicone and others.

A wide range of silicone sealants Tytan produces the Polish company Selena. Products belongs to the class of professional products and have a competitive cost. The cost of one bottle (310 ml) ranges from 1.5 to $ 2.

For work in wet rooms, acid sealant is like Ceresit CS 25 With a high content of fungicides. A universal sealant is often used to seal building glass blocks, windows and doors Moment.

Tips for choosing optimal sealant

Here are some tips that will help you choose a high -quality silicone sealant:

- When buying, you need to study the composition of the material. High -quality sealant contains:

- 26% silicone;

- 4-6% rubber organic mastics;

- 2-3% of thiocol, polyurethane and acrylic mastics;

- not more than 2% of epoxy resins;

- up to 0.3 % of cement mixtures.

- The sealant density is less than 0.8 g/cm indicates the low quality of the goods.

- Hermes that have antimicrobial properties cannot be used for products in contact with food and drinking water. Such products are not suitable for aquariums, terrariums.

- The goods must have an accompanying and warranty documentation.

- To eliminate minor cracks in the windows, a sealant for external seams is suitable. It does not crack under the influence of sunlight and will cope with temperature fluctuations.

- To work with dark wood, grouts of a photo collage and mosaics it is better to choose a transparent silicone.

- It is advisable to decorate the floor seams with a sealant of dark shades.

Sea sealing: step -by -step instructions

The use of silicone sealant is quite a simple process that can be divided into the following stages:

- Clean the processed surface from dust, dirt and dry thoroughly. Small metal parts with a solvent.

- Install a tube with a working substance in a silicone gun.

- Open the packaging with a knife cut off the tip of the nose and wind up a special dispenser. To regulate the thickness of the silicone supply strip, the dispenser is cut in a certain place.

- Before processing decorative surfaces, they must be protected from pollution. Molar tape is suitable for these purposes.

- The silicone is carefully squeezed from the tube and evenly distributed on the surface of the product.

- After finishing work with sealing material, remove the painting tape.

- Excess silicone should be removed with a damp cloth, wash your hands with soap. This must be done immediately after work.

- The drying time of silicone sealant depends on its type, thickness of the layer and external conditions (humidity, temperature). On average, the silicone completely freezes 24 hours after application. The upper layer of sealant is covered with a solid film literally after 20 minutes.

Safety precautions when working with sealant

Store silicone sealant at room temperature in an inaccessible place for children. Shelf life 1 year. During operation, the contact of a non -hardened silicone with eyes and skin should be avoided. If the substance gets into the eyes, they must be immediately washed with cold water.

Particular caution should be observed when applying acid sealant. In the process of vulcanization, such a material emits vines of acetic acid, which can cause irritation of the respiratory tract and eyes. Therefore, all work with acid silicone should be carried out in a ventilated room or put on a protective mask (respirator).

How to clean the surface from sealant correctly

If the excess silicone sealant did not work on time, then the surface can be wiped using one of the means:

- White Spirit.With mechanical cleaning with white spirit, it is necessary to act very carefully, since the substance can damage the product. If the surface was painted, then the paint will be erased with silicone.

- Foam-840 Specially designed washing of silicone. The composition completely destroys silicone and allows you to remove the sealant without damage to the product. When choosing a foam-840, it is necessary to take into account the type of surface processed. If a thin film remained after washing, then it can be removed with acidified water (acetic acid, lemon juice).

- Antilicon Cleaning agent based on organic solvents. Used to degrease the surface, removal of polishes and silicone. Suitable for working with plastic, steel and aluminum surfaces, stainless and galvanized steel, polyester putty and primer.

Silicone sealant universal material, indispensable during the implementation of various repair and construction work, both in everyday life and in production. Professionals and amateurs each time find non -standard and effective solutions to use silicone putty.