Today, many developers choose the construction of a columnar under their house ...

|

|

In the field of construction, one of the most famous manufacturers of insulation is considered ... |

Speaking about skirting boards, we mean most often those that are intended for ... |

How to choose veneered doors

The interior door is not just an element, for the separation and isolation of individual rooms of the room, but a bright detail of the interior. With the right choice, it emphasizes all the advantages of the room and visually increases it. Sponge doors cope well with all these tasks. Not inferior in their characteristics laminated doors, they have a structure of natural wood and an affordable price.

Content:

- Technology for the manufacture of veneered doors

- Types of veneer

- Characteristics of veneered doors

- How to choose veneered doors

- How the veneered doors differ from each other

- Proven manufacturers of veneered doors

- A variety of veneered doors

Technology for the manufacture of veneered doors

Before choosing good veneered doors, you need to find out more about the technology of their manufacture.

There are 3 ways to apply veneer to the surface:

- Cold veneration is carried out on glue with pressing;

- hot venction is also carried out on glue, but of a different composition with better characteristics and using a hot press;

- the membrane-vacuum venction method is used to create a variety of design. Thanks to this method, the veneer is superimposed on the surface with any relief.

By type of design, the veneered doors are divided into two types:

- solid. The wooden frame is filled with glued wood;

- hollow. The frame is made of an array of wood and is connected by molding or phylene panels from veneer.

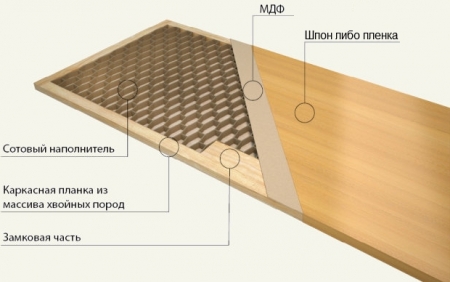

Hollow design of veneered doors

The basis of such a door is a frame of a pine beam with a section of 30x33 mm. To avoid further deformation and the formation of cracks, the moisture content of wood should not exceed eight percent.

If you need to install glass, then an additional frame is mounted along the entire perimeter of the double -glazed window. It is a horizontal strip with a groove, with which they are attached to the outer frame.

Then, on one side, the frame is closed with a panel of MDF with a thickness of 4 mm. The formed space in the thickness of the beam is filled with polystyrene slabs or cellular cardboard. On top everything is closed by the second panel from MDF. The result is a three -layer pie.

Now the stage of preparation of veneer for plyting begins. The strips of a natural veneer 30 cm wide are folded in sheets of the required size (which is slightly larger than the size of the door leaf). To achieve a mirror repetition of the figure of the door leaf, each of the stripes is selected in color and texture. When all lanes of veneer are selected, they are glued with adhesive tape on a special machine. Further, excess glue is removed from the finished sheets, after which they are adjusted by the size of the door leaf.

The stage of the veneer came directly to the door. At first, he is attached to the front parts from the MDF, and only then to the end. To do this, glue is applied to the MDF panel and a leaf of veneer is placed on top of it. Under hot pressing, the glue is baked, reliably connecting both surfaces among themselves. After several grinders, the door is covered with protective varnish, which allows the use of veneered doors even in rooms with high humidity.

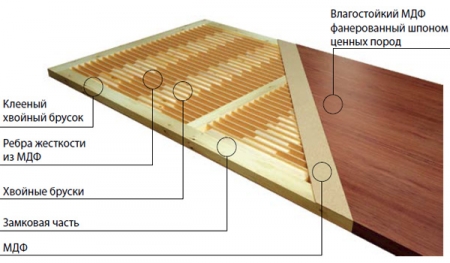

Solid design of veneered doors

A pine beam is also used for their manufacture. But they do not make a frame from it, but a whole canvas, gluing bars with a hot press into a monolithic shield.

Explored with profile milling and polished workpiece is glued with MDF panels. Veneer coating occurs according to the technology already described above.

If desired, you can finish the metal door. To do this, MDF sheets are attached to self -tapping screws, and an veneer is already applied to them. With this method, it is recommended to attach a natural veneer to the side, turned into the room, and on the outside is artificial.

Types of veneer

To date, manufacturers are offered three types of veneer:

- natural;

- multishpon;

- fire -ine.

Natural veneer

It is a thin sheet of natural wood. It is removed from the wood by deservation, cutting or stricting. He got his name due to the complete maintenance of the texture of natural wood. Doors with this coating are more expensive than from chipboard, but cheaper than from a natural array. At the same time, it retains all the aesthetics of real wood, environmentally friendly, and the pattern is unique.

Fire-line veneer

This is a sprum reproduced using a special technology. It imitates various species of wood, conveying their texture and shades. For its manufacture, fast -growing types of trees are used. The production technology consists in the formation of blocks from a sponed veneer, and further production of them variable in color and size of veneer. Thus, preserving all the environmental friendliness of natural material, new and various textures are created.

Stages of wood processing:

- lugging on special equipment. As a result, logs are divided into thin ribbons and cut into small sheets;

- the resulting material is dried and sorted by color;

- for through staining, the sheets are lowered into a container with a coloring solution;

- the painted material is compiled in packs and glue. The resulting block is pressed under high pressure. In the future, from it they receive the necessary sheets of veneer.

- As a result, there is 93-94% of natural wood, 6-7% glue and 0.2-0.3% dye in such a veneer.

The advantage is the absence of knots and cavities that are found on a natural tree, as well as the possibility of choosing a texture. Of the shortcomings - high porosity of the material and a high glue consumption during venction. In addition, the veneer obtained by this method is quite fragile.

Multishpon

This is a reconstructed veneer made of natural wood. It retains the texture of wood less than all other species. Decorativeness is given to him by geometric patterns and combinations of different color shades. The doors covered with multishpone look modern and great for the interior in the Art Nouveau style.

Among its advantages are environmental friendliness, a wide range and uniqueness of the drawing, durability and undemanding during operation.

Characteristics of veneered doors

The main advantage of veneered doors from MDF is a combination of natural beauty of natural wood with low price.

Advantages:

- the uniqueness of the texture and colors;

- high resistance to temperature changes and high humidity in the room;

- the ability to repair the surface with small injuries;

- high heat conservation and noise insulation;

- environmental friendliness.

Flaws:

- the difficulty of picking up several doors similar to the texture;

- under prolonged influence of sunlight, the veneer can darken.

In addition, the accuracy of compliance with production technology and the choice of material has an important effect on the duration of operation. Therefore, even veneered economy class doors are recommended to be bought only from trusted manufacturers.

How to choose veneered doors

When choosing doors, a number of rules are observed. First of all, it is worth paying attention to the price of veneered doors. The desire to save is clearly, but it should be realized that the door, covered with wooden veneer, cannot cost as much as covered with plastic. Just because the price of wood is much higher than for PVC panels.

If you need to buy several doors, then you can contact the manufacturer or their official dealers directly. This will be good to save without prejudice to quality. Direct contact with the official representative of the plant will order the doors of non -standard sizes according to individual sketches.

And if necessary, get a qualified advice on the manufacturing technology and quality of the material.

When choosing veneered doors, it is necessary to focus on the color scheme of the premises in which they will be installed.

Even the highest quality and most beautiful door will not look beautiful against the background of objects and things that it does not fit in style or color.

Not only deaf veneered doors are made, but also with various inserts. It can be a matte, simple or decorated glass, multi -colored stained glass, an insert of any natural material (for example, bamboo or rattan). They are more expensive than deaf, but also look more aesthetically pleasing.

When choosing an veneled door, carefully consider its pattern. It should be unique, and if repetitions are observed, it means that the manufacturer used an unnatural veneer, the price of which is significantly lower.

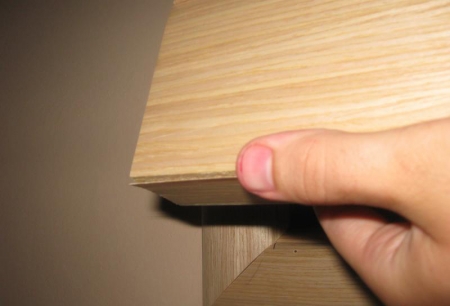

It is necessary to check how firmly the veneer is glued to the door. It is easy to do this, it is enough to pick up the edge of the veneer at the end, if it has moved a little, then a low -quality door.

At a good veneered door, the surface is smooth and does not distinguish any chemical odors.

Recognizing all the advantages of natural material from which the veneered doors are made, many still prefer doors with an artificial coating. The only argument of this choice is savings. It is worth noting that high -quality laminate, which is covered with the door, is not much cheaper than a natural veneer.

Before the final purchase, make sure the seller of the configuration. The veneered door should have not only a door frame, but also platbands.

How the veneered doors differ from each other

A wipped door does not always mean a high -quality product covered with natural wood. In stores, a low -grade fake appears more and more, which at first glance is quite difficult to identify.

To increase competitiveness, unscrupulous manufacturers produce cheap doors from low -quality raw materials. To save, the manufacturing process changes, which also negatively affects the quality of the product. Thus, acting on the lack of professional knowledge among potential consumers. Therefore, it is so important to be guided not only by the low price when buying veneered interior doors.

Possible constructive defects of veneered doors:

- in the production of solid doors, not glued beams are used, but ordinary, with knots and other defects. This will lead to the deformation of the door during operation;

- sometimes instead of a wooden array for the door frame, chipboard is used. This is not only a rough fake, but also the difficulties in use. Often, when, under the weight of the door leaf, the self -tapping screws are pulled out of the chipboard, with which the door loops are attached;

- for savings, they can exclude a layer from a MDF sheet between a beam and a veneer;

- there are also doors in which the joints of the bars are visible through the veneer, and the surface has cracks, breaks and irregularities;

- the domestic PVA glue is used as adhesive substance for veneer. In the future, such a door is most likely to be deformed;

- there are no grooves for their fastening. As a result, they will have to be installed on nails whose hats will be noticeable;

- doors are equipped with poor -quality fittings. It is difficult to replace it independently.

All these gross mistakes are quite difficult to notice at once. And even the proposed cut of the door cut, which is made according to all the requirements, may not be true.

The quality of the finish itself is also important:

- a rough coating means poor -quality grinding and the use of inexpensive varnish;

- the heterogeneity of the coating and the noticeable pores of the tree indicate an too thin layer of varnish. In the room with wet air, such doors will not last long;

- the technology impaired varnish from the door box and platbands, the uneven coating, the difference in the color of different elements of the door, insufficiently polished edges and corner doors, the presence of chips and plucked places.

When assembling, the following shortcomings are found:

- mismatch of the profile of the joined elements of the door frame;

- low -quality installation of accessories (chips, cracks);

- unstable geometry, poor fit between the lining and glass, the mismatch of the size of the box and the canvas.

The service life of low -quality veneered doors from 20 years is reduced to a maximum of two. Therefore, a good at first glance saving in 50% can turn into high costs.

Proven manufacturers of veneered doors

You can protect yourself and buy a good door only from manufacturers who care about the quality of their products. The most famous Russian manufacturers are Veles and Bravo. They produce high -level doors at an affordable price. The products of the company are also popular, which belongs to the category of elite.

Such companies as Pope Carlo and Carlo Porte are not inferior to them. Over the years, they produce high -quality products, and even during the crisis and a decrease in sales they did not change themselves, retaining the achieved level.

But perhaps the most popular doors in Russia are produced at the Italian Imola plant. Over time, this name has become a household name and means a smooth hollow, covered with veneers.

The most budget doors are made in Belarus. Despite the low price, the doors of the Volkhovets, Sophia and Alvero factories comply with all the requirements and standards of high quality.

There are a number of manufacturers whose doors are represented in stores of most cities and which you can safely trust: the Alexandria doors, Mario Rioly, Karelian doors, Yaroslavl doors, Framir, Yaroslavl doors.

A variety of veneered doors

Doors veneered by economy class. Today it is the most popular type of interior doors. Having an expensive look imitating an array, they have an affordable price for most consumers.

Duba veneer door. For rooms in a classic style or in a chalet style, beautiful wooden doors from valuable wood of wood should be installed. But the cost of doors from an array of oak is very high and few can afford them. A wonderful alternative is doors with oak veneer. Outwardly, they completely imitate an array, and in some technical characteristics they even surpass natural wood.

Sponge doors of a white oak. Wooden veneered doors of light colors are great for any interior, emphasize its beauty and visually expand the space. They are unpretentious during operation and durable. And thanks to modern technologies, a white veneer of oak is flat and with a delicate pattern, which gives the doors a special charm.

Smooth veneered doors. They are very popular among types of interior doors. Combine aesthetics and affordable price. Outwardly, it is almost impossible to distinguish them from an array of expensive wood.

Veneered doors in the interior photo