The hall plays a particularly important role for us, since there we spend a lot of time ...

|

|

There are many options for mounting the flooring, but laminate laying ... |

Wooden houses, baths, saunas and cottages have an important advantage, they are completely ... |

Making an interior door with your own hands

Often, a dispute arises between the owners of city apartments, whether it will be possible to make interior doors with their own hands. And this conversation usually divides the discussing people into two sides. Here, the most important thing is to understand or rather take into account the fact that the doors can be different in design, and therefore all difficulties in the manufacture and discussion on a similar topic arise. However, contrary to the fact that opinions are separated, you can make interior doors yourself.

Table of contents:

- The design of the interior door

- Types of coatings

- Types of interior doors

- Characterization of materials

- Preparation of tools for work

- Production of an interior door

The design of the interior door

Interior doors are an important part of the interior of the room and the entire dwelling as a whole. Doors allow us to feel protected. Interior doors perform important functions isolate residents from the smells, sounds and other people present in the apartment. To date, two basic varieties of interior doors are distinguished. The designs of such doors differ from each other. Filenced -type doors consist of a frame inserted into it of a philanic and glass. The site that is released by profiled thin frames and a plastic or plywood shield, and which closes the frame, is called a phicen.

Filenced doors are characterized by excellent sound insulation and lightweight. For your own manufacture, the phylene door is not suitable, because it has a complex design, and one watching video about the manufacture of an interior door is not possible here. Interior shield doors are primarily used to independently arrange residential buildings. They consist of a smooth shield, which you can faced with plastic or plywood. The advantage of such a variety of doors is an affordable cost and excellent quality. In addition, such doors are universal! They can be installed as input for the bathroom and as interior.

Types of coatings

There are four varieties of coatings that are used for doors: rationing, lamination, painting and tinting. The simplest coating methods are tinting and staining.

The array and MDF doors are painted. A layer of paint is applied to the canvas, sometimes two or three layers. The quality and durability of painted interior doors depends on the paint and equipment that you use. When tinted, it is customary to cover the doors with varnishes - translucent or transparent. Using this method, it will be possible to most clearly convey the texture of the tree. Doors are best suited for tinting that are made of hard wood, because minor scratches and dents will remain on the soft tree.

When laminating, they are suppressed on the basis of the film without the use of glue. The film is used plastic or paper, which is used almost always. When veneering, a thin film made of wood is glued to the door leaf. It is desirable that its thickness is more than 1 millimeter. The veneer is usually applied to the substrate, and then covered with varnish. The venction is intended for an array and for interior doors from MDF.

Types of interior doors

Today there are many types of interior doors that differ in the method of opening. But the main types are five: swing, pendulum or swinging, compound doors or sliding, folding or harmonica doors, as well as stables.

Swing doors are the most common view, they open in one direction. Are one- or double. If the canvases are of different widths, then such doors are called one and a half -root. According to the installation options, swing interior doors are left that open from you to the left, and right, if the door opens from you to the right. Their main drawback, noticeable especially in small rooms, is that space is necessary to open them.

The pendulum doors are considered a subspecies of doors that have a swing system of opening, but at the same time they have their own highlight. Their distinctive features lie in the fact that the pendulum doors open in both directions. True, due to this characteristic, they are not too common and are more individual in the nature of use. You are unlikely to see the swing doors in an ordinary city apartment of a multi -storey building. But you will definitely find them at the entrance to the metro. Swing doors are aluminum, glass or plastic.

Interior capuas-capacity can open by shifting the canvas inside the wall or along special guide rails. They look more aesthetic when they are able to move inside the partition. Licking doors are ideal for rooms with a limited area, because for opening they do not require additional space.

Folding interior doors are made of separate panels, which have a width of 10-15 centimeters, which are folded when opening to the edge of the opening, or can go inside the wall. The noiselessness and ease of sliding panels are provided with bearings, which are built into rollers. The panels can be performed deaf or glazed. For glazing, it is customary to use stained glass or ordinary glass. But this is two times more expensive compared to the deaf doors.

The stable doors are a variety of ordinary swing doors. Initially, they were installed in the stables, which is why these doors received such a name. The stable doors are two halves, each of which has its own loops and locks. A similar type of interior doors is particularly popular in the West. But in a home environment, such products will be appropriate as the protection of children, because the lower part is capable of blocking their way to the street. The stable doors are best installed in the kitchen.

Characterization of materials

In past times, the doors were made of natural wood, but time moves forward. And today there are many substitutes that imitate natural wood. Combined or artificial materials are an order of magnitude less in price than natural wood. But this does not mean that the technology for the manufacture of interior doors made of wood has sunk, on the contrary, in our time they are several times more expensive, but as before the leading positions in this industry are occupied.

Wood

Among coniferous breeds, pine is mainly used to create doors, which has become widespread due to its cheapness. A lot of people are very pleasing to colorless varnish, many people are very pleased with their beautiful light color and a drawing with dark spots. It should also be borne in mind that pine is a rather soft material and with a slight blow with sharp objects on a wooden canvas there remains a noticeable recess, which spoils the overall cosmetic appearance of the canvas.

Among the door installers, there is often the opinion that interior doors made of pine should not be placed in moist rooms, such as a winter garden, a bathroom, a pool due to the fact that when the air is fluctuated, the pine tree exiles and is dry, that is, there is a deformation . Everything could be so, however, with proper modern processing with special quality materials, this poor property of pine disappears completely.

The following materials are more expensive and richer: beech, oak, maple and red tree. The cost of this material depends on the beauty and overpassness of this tree relative to other conifers. The life of such doors with proper manufacturing, processing, competent installation technology and care measures are for more than one decade.

Artificial materials

Artificial substances for the manufacture of interior doors with your own hands, for example, chipboard and MDF, certainly cannot compare with natural wood doors, their durability and strength, but their price is much lower than the doors made of natural wood. The useful life of such doors is less, and the environmental qualities of such doors remain in doubt, despite the fact that manufacturers guarantee that they are environmentally friendly.

Typically, interior doors made of combined materials are mainly represented by MDF, chipboard and veneer of valuable rocks. When covering the door leaf, quite expensive veneer, then almost the appearance does not differ from natural wood, because the veneer is made of wood. The strength and time of service can be said that these parameters are almost no different from the qualities of natural materials. Interior doors from combined materials are the cheapest and not be afraid of moisture fluctuations, so they are less exposed to deformation than an analogue of natural materials.

Glass

Considering all the materials that can be involved in creating interior doors, you should not forget about such a material as glass. Glass inserts in the doors are an original decoration of the interior door and the interior as a whole and carry some functionality in themselves. Thanks to the inserted glass, much more daylight enters the room through the door leaf, and this is very important for darkened rooms.

Due to the variety of color shades of glass, you can set a variety of design in the room. The glasses are different: matte, transparent, multi -colored, with drawings and patterns. The safest glasses are hot ones, which, when broken, are divided into very small pieces, but at the same time they are not able to harm a person. Glasses are strongly recommended to install in the children's room.

Metal

When interior doors are made, metal is used. Loops and pens are made from it. The cost of accessories usually depends on the design, the convenience of using the product and coating. The loops can be universal and connective. The advantage of connective loops is easy and quick removal.

To remove the door, you should just raise it up, and it will be quite easy to remove from the hinges. Such loops, unlike universal, open the interior door to the right or left. Universal loops are designed to open in any direction. But to remove the door from universal loops is much more difficult than removing ordinary doors.

To remove them, it is necessary to disassemble the loop, for this, pull out the rod in the middle. There are loops on sale, thanks to which the interior door will open in both directions, depending on the direction where the person moves. The price also depends on the design and on the material from which the door handle is made.

Do not forget about the inconspicuous material, which is called the seal. It is not noticeable with a closed door, but you must know that it performs an important function, for this it is installed. The material performs functions such as an increase in sound insulation, an obstacle to heat leakage, as well as the entry of extraneous odors and dust into the room. Make seals from various materials, they come in various sizes and colors.

Preparation of tools for work

The manufacture of a purple door is a very complex process that requires certain knowledge, skills and experience. But along with this there are interior doors, which are simple to manufacture and which do not need special skills and require a minimum of tools. This is a screwdriver, a hacksaw, a kitchen knife or chisel, roulette or meter, as well as a piece of a large sandpaper.

For the manufacture of doors, you will need the following materials:

- Thick boards are about 50 millimeters or a beam for a box: two timber for the vertical part and one shorter for the horizontal part;

- Reiki or bars for the frame: 2 long bar for the vertical part and 3 short for horizontal parts of the door leaf;

- There is so much fiberboard so that you can sheathed the doors on both sides;

- Self -tapping screws and glue for connecting parts;

- Materials for finishing: decorative film, venerable plywood, paint and varnish depending on the design of the future door;

- Furniture for doors: pens, loops, locks (latches) - all of your choice.

Production of an interior door

There are openings in the walls of your houses that require the installation of the door is an axiom. If such an opening is at the entrance to the residential building, then the best option would be to install the table door. The cheapest door is considered the one that is redone with your own hands. We start alteration! We remove the door from the loops that we are going to redo, and put it on the table, after that we remove all the accessories, that is, loops, pens and lock. After we dismantle the door, you need to decide how it will look after alteration.

Decide whether it will look like a continuous surface, or you want to make it with a window binding. The second option will be somewhat more complicated, although in the first one will have to remove the old paint from a large area. The following will be told how to create doors with a window binding, which equipment for the manufacture of interior doors, and how to sheathe the veneer of the entire surface.

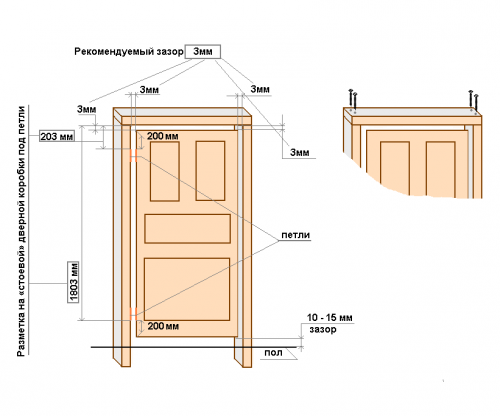

The first stage is the markup. To do this, use a large square! Typically, marking is made using a ruler and a square, the lines are applied with a marker or pencil directly to the door surface, on the paint on it (it will be removed). Make such indentes on the sides of the door: more than 160 millimeters on top; below - more than 500 mm; On the sides of about 105 millimeters.

After the marking has been applied and determined with a fragment of the door leaf, which will be removed, we take the drill and make 5-7 holes in the marked corners with a pitch of 3-5 mm. Next, we cut all this, while using a hacksaw, we also control that the lines turn out strictly straight.

Next, we take out the sawed fragment, insert it along the contour of the future binding, between the cardboard panels of the skin or plywood, lubricate the wooden rails with carpentry glue. If, when installing the rails, cardboard ribs located between the casing will interfere, it is recommended to break them to the required depth with the help of pliers. The glue will dry for a couple of hours. However, you should not wait for the glue to dry, fix all the slats around the perimeter with small nails 10-15 mm long, lifting their hats into the casing.

Now your interior door is made and installed. You have learned to choose the right material for this product and know what tools you need. You can take after that and for more complex tasks. And information can be gleaned from our next articles!

logright is sensible

logright is sensible