Accessibility, durability, unpretentiousness, versatility is far from ...

|

|

The house repair is forced, but some finishing materials give ... |

The range of flooring has dozens of different names. Among all ... |

DIY Filenced doors

Being an obligatory element of any interior, interior doors perform not only operational, but also a decorative function. The constructive and functional features of the phylene doors allow them to successfully combine both directions in themselves, so that the phylene doors are not only a reliable, but also an attractive element of the interior. However, their popularity is due not only to double functionality, but also by many other advantages that distinguish phylencial structures from other varieties of interior doors that will be considered in this material. If you prefer phylenny doors, it is not necessary to purchase factory structures completely simply to make them yourself. It is worth noting that homemade models are characterized by some advantages that are not characteristic of factory products. The advantages of homemade models, as well as the features and step -by -step instructions for their manufacture are also the subject of consideration of this article.

Content

- Filenced doors: definition and brief excursion into history

- Features of the design of the phylene doors. Types of philanic

- Popular materials for the manufacture of phylene doors and their advantages

- Production of phylene doors from a pine massif: nuances and features

- Advantages of phylene doors made by yourself

- Materials and tools for the manufacture of a phylene door

- Step -by -step instructions for the manufacture of an interior phylene door

- Finishing of the phylene door as the main component of its long -term operation

Filenced doors: definition and brief excursion into history

Having become the first models that appeared in the Russian market of interior doors, the phylene doors quickly gained popularity among consumers, which is due, undoubtedly the optimal ratio of price and quality. In the 90s, the most popular model became white doors, made from MDF and clearly proved their effectiveness and durability.

What is a phylenka? Ushakov’s dictionary gives the following definition of a given term: a phylenka is a thin plywood or a board that is inserted into a frame made of any materials.

Accordingly, we can conclude that the phylene doors are doors, the design of which implies the presence of a frame, most often wooden and performing the role of the supporting element, as well as inserts of the phylenka. It is worth noting that in modern phylene doors, an insert can be not only wooden. But in most cases, phylenka are made of wooden array or combined materials, which include MDF and a pine massif.

Features of the design of the phylene doors. Types of philanic

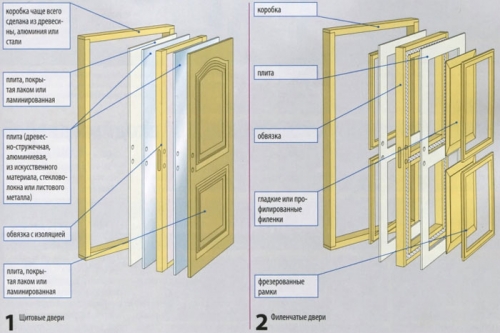

Filenced doors are almost impossible to confuse with some other varieties of interior doors. Their design features are similar to those for the usual window, since the latter, consist of a visible frame that plays the role of the frame, and the thinner inserts-films. Thus, the main constructive elements of the phylene door are the following elements:

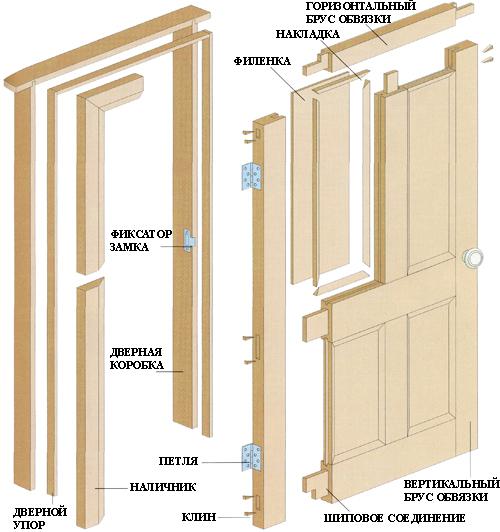

- A wooden frame, also called a strapping, is the main element of the structure, on which the remaining parts of the door are subsequently attached. Its manufacture is carried out from a solid array of wood, as well as glued beams. Most often, the frame is made of four parts interconnected. To increase the strength of the structure, the lower part of the frame is made somewhat wider than the side and upper. A more modern approach to an increase in the strength of the phylene doors is to strengthen the entire bottom of the structure, which is sheathed with leaf metal, for example, aluminum or galvanized steel. However, it is worth noting that the use of such a technique is relevant to strengthen the design of only the input Phillo doors;

- Middle peasants, which are horizontally located bars, fixed in the middle part of the canvas;

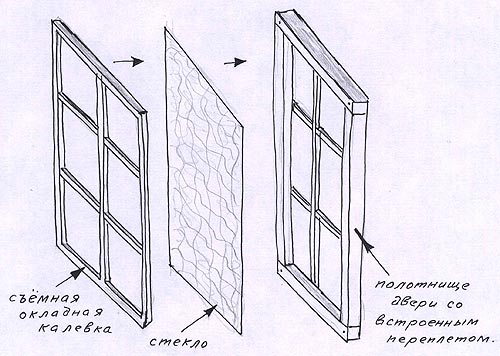

- Filenok, which can be made from various materials and are fixed in the door frame. Often they are the main decorative element of the door. They are decorated with painting or given to them the most bizarre form. For their manufacture, various materials are used, most often it is glass, chipboard, MDF or plywood. Fragments are inserted into special grooves, after which they are fixed with the help of decorative stacks (often it is a graduates with surfaces that received such a name, since part of them enters the door plane. These features provide the ease of replacing the damaged fragment, for example, broken glass, and They also allow you to radically change the appearance of the interior door.

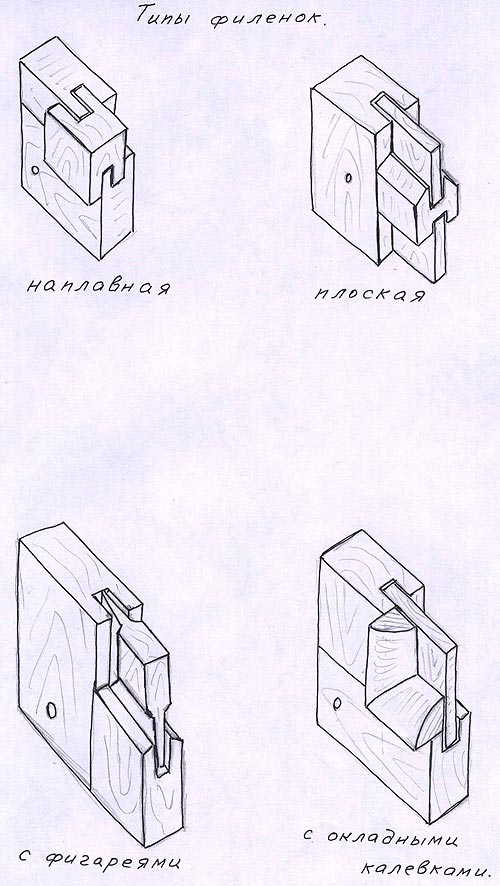

The main varieties of phylenoks

- Traditional smooth philles made from the same strips with a flat surface. They can be used for the manufacture of both entrance and interior doors;

- Figar Filenchi, a distinctive feature of which is the presence of a convex middle part, gradually thinning to the edge;

- Files, for the manufacture of which were used boards of the same thickness as for the manufacture of the frame;

- In addition, there are double and single Philines. To assemble the single, the strips laid in one row are used, while double are made of two rows of strips, separated by a layer of insulating materials or an air gap.

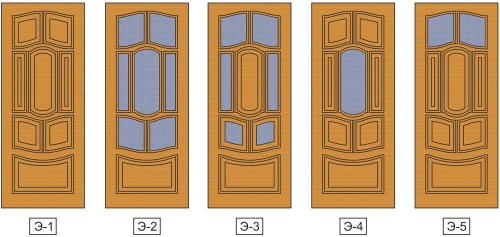

Filenced doors photo

Popular materials for the manufacture of phylene doors and their advantages

Often, the manufacture of phylene doors is made of whole wood massif. The breeds used in this case can be very diverse: from those that are everywhere found in the territory of the middle lane, to exotic varieties brought from the most distant corners of the planet. The choice of breed has a significant impact on the cost of the finished product, and often on the timing of its manufacture, which can be quite variable. For the manufacture of phylene doors, only selected, carefully dried wood is used. Not only breeds of low price category, such as pine, birch or spruce, but also medium -sized, but at the same time more strong grab, oak and beech, which, in the case of proper operation, will serve for several decades, are in wide demand.

The most common material for the manufacture of phylene doors is pine boards, a distinctive feature of which is a pleasant honey tint, attractive texture and ease of processing, and natural antiseptics that enter the structure of wood allow the material to maintain their original characteristics for a long time. The unique features of the material allow you to install doors made of a massive pine, you can install not only as interior, but also the entrance doors. This is due to their high strength and wear resistance, which positively affect the operational period of the door leaf. Thus, the popularity of wooden philanthrous doors made of a pine massif is due to their following advantages:

- Manufacturing from natural ecologically pure raw materials, which during operation does not pollute the atmosphere with harmful evaporation, as a result of which it is absolutely safe for human health. Despite the fact that a pine massif is a material related to a low price category, its durability leaves no doubt and is in the optimal ratio with the price. In the process of proper operation, they will not only last more than one decade, but will not lose their original characteristics;

- Resistance to mechanical influences Allows the doors made of this material to maintain strength and resistance to mechanical damage. It is especially important that the pine array retains resistance to moisture and temperature changes, which determines the possibility of installing a phylene pine tree as external doors;

- Aesthetics and decorative properties It is also difficult to ignore. The pine massif has an attractive texture and color, so the phylene doors can become a decoration of any interior, and their external counterparts will noticeably embellish the exterior of any home;

- And, of course, a very democratic costwhich cannot go unnoticed. It is thanks to moderate pricing policy that you will receive a high -quality and reliable door at a low price.

Production of phylene doors from a pine massif: nuances and features

Currently, there are several ways to make a phylenny doors from an array. Manufacturers offer several main production methods:

- Manufacturing of phylennic door leafs using glued pine beams;

- The production of doors made of natural massif pine, which excludes the use of certain additional substances.

Each of these methods has its own advantages and disadvantages. As for the first method, in practice it is carried out quite easily. Doors made of glued beams have undoubted strength and resistance to aggressive influences of the external environment, since in the process of gluing the bars are firmly attached to each other and it is almost impossible to tear them away from each other. Having carried out gluing the bars, they are thoroughly dried, after which they are covered with varnish, which contributes not only to an increase in their strength, but also to aesthetic characteristics. Due to their high strength, phylene doors made of glued beam are installed as external;

If we consider the second method, it can be noted that the manufacture of a phylene door from a natural pine array represents certain difficulties, in view of which in most cases such doors are made to order, and the cost of this event is often quite high.

Advantages of phylene doors made by yourself

If you decide to install a phylene door, it is not necessary to purchase a factory manufacturing option. If you have a little experience and skills of a home master, it will not be difficult for you to make a phylene door with your own hands, especially since in this article we will give step -by -step instructions for its manufacture. Consider the main advantages of the phylene doors made independently:

- The lower cost of homemade doors, unlike their factory analogues;

- Independent installation of phylene doors by certain standards will save you from the need for their fitting to the dimensions of the doorway;

- Given the certain features of the manufacture, homemade phylene doors differ in less exposure to external influences, and therefore, they are less destroyed under the influence of temperature differences.

Materials and tools for the manufacture of a phylene door

Before you make a phylenny door, stock up on a very modest set of tools.

Necessary tools:

- Hacksaw for wood work;

- Chisel and screwdriver;

- Pencil and roulette;

- Sandpaper with fine and large grain;

Initially, decide on the materials for the manufacture of phylene doors. To make a reliable and strong frame, it is necessary to choose wooden rocks with high strength characteristics and resistance to changes in the environment and microclimatic parameters. Thus, it is better to opt for the most durable wood species, such as oak or ash. Pine is also a durable material characterized by the optimal ratio of price and quality. It, like previous breeds, is resistant to the differences in microclimatic parameters, such as humidity and temperature.

It is better to choose a chipboard or plywood as materials for the manufacture of philanthones, which will make the design light and, at the same time, inexpensive. If you want to make the doors more massive and solid, use a more expensive tree of wood. To increase the decorative characteristics of the door, they often use glass inserts, which can be matte or transparent, as well as a decorated most diverse pattern. Doors with stained glass inserts look very expensive and solid.

Since real design stained -glass windows are more than expensive, they often use decorative glass painting, which is made two -sided to create the effect of a full -fledged stained glass.

Necessary materials:

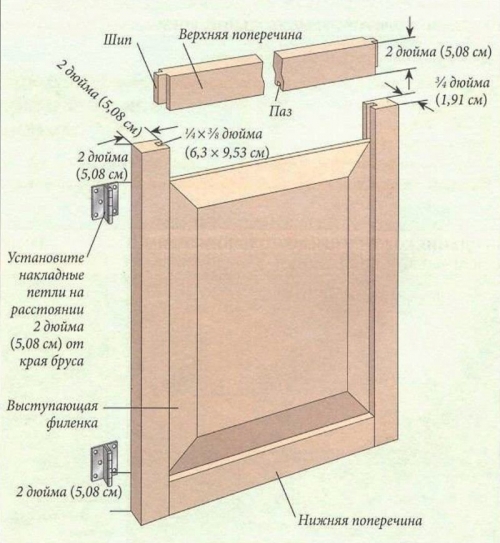

- For the manufacture of the frame, we will need thick boards with a width of up to 50 mm or 3 bar, 2 of which will go to the manufacture of the vertical part, and 1 to create the transverse upper part;

- For the manufacture of philanthones, stock up on plywood or chipboard, at your desire they can be replaced with glass. If you plan to make files made of glass, additionally prepare the glazing staff;

- In addition, we need glue and screws;

- Door accessories (door loops and handles);

- As well as materials for the final decoration of the door (various specialized coatings, varnishes and paints).

Step -by -step instructions for the manufacture of an interior phylene door

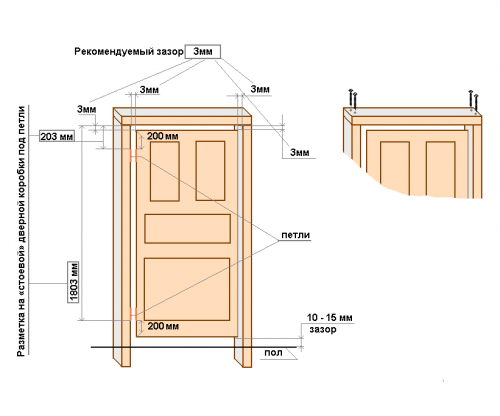

The initial stage of installation is the installation of the doorway. It should be made in such a way that any distortions and differences in the width and height can be easily excluded. After making a door frame, you can proceed with the installation of a phylene door with your own hands;

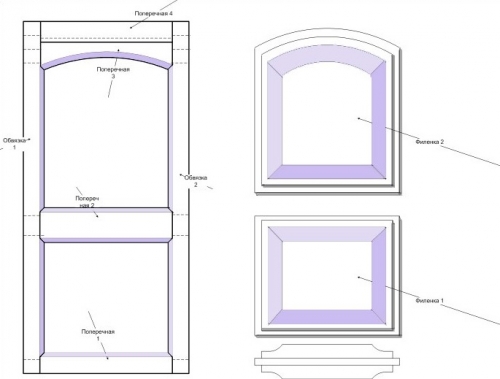

It is better to start its manufacture with the development of a sketch, which is created taking into account your personal preferences. However, experts advise a novice master to start with the installation of a door with six Philines. Having created an approximate sketch of the door, it is detailed, they note all the necessary sizes on it, after which they purchase the necessary materials according to the selected sizes;

Then proceed to the manufacture of the frame. To do this, using a roulette, measure the width of the doorway.

It should be noted that the dimensions of the door will be 4-6 mm smaller than the sizes of the door frame.

Given the resulting size from the beam, the base for the door is made. To do this, on a bar, devoid of mechanical damage and irregularities, is noted with a pencil of the necessary length. The excess part is drank with a hacksaw. As a result, 2 main vertical racks and 2 transverse, which are fixed in the lower and upper part of the structure, as well as internal transverse rails, which serve to increase the strength of the structure, should be obtained.

In order to fasten the parts tightly with each other, grooves and spikes, perfectly suitable in size, are made in the right places. To increase the strength of the mounts, the parts are coated with carpentry glue, and in the places of attachment the phylenenoks make chamfers.

Having made the frame, proceed to the installation of philanic. If you use wood, then it is better to opt for the boards of the board this will avoid creating a team chamfer. In accordance with the size of the chamfer, the finished part is cut out of the array and spills are made at its edges, which will allow you to tightly fasten the part with the chamfer.

If you do not have the opportunity to create a files from a solid massif, but you still want to use wood, make phyilens from pieces of wood, holding them together using a system of grooves and spikes, and additionally smearing the joints with carpentry glue. After you make a phylenka from pieces of wood, make a sawing saw on the edges of the beam.

Important!Files made of array can be additionally decorated with an additional pattern, but this is necessary for special skills and tools.

If the Philines are made from chipboard or plywood, they are cut out in accordance with the necessary dimensions.

If you plan to make glass inserts, they are also cut in accordance with the sizes of the door, or in the manufacture of transverse slats and jumpers are guided by the size of the inserts.

If you decorate the door with glass, decorated with bilateral painting with imitation of a stained glass window, the pattern is applied before the file is inserted into the frame. Glass Philles are fixed using graduates, since this method allows you to replace the insert in case of damage.

Finishing of the phylene door as the main component of its long -term operation

There are two main methods for processing the phylenny doors, the first of which is called continuous and implies the same design of the frame and phylenka, and the second contrasting, implying the obvious release of the phylenka.

The finish of an interior or entrance door made of a pine mass consists in treating its surface with antifungal, as well as antiseptic drugs that protect the surface from aggressive influences of the environment, and also give the tree refractory properties and impede wood aging. However, unlike other methods of processing, for example, enamel painting, antiseptic solutions do not hide the texture of wood and due to the entering the antiseptics of coloring pigments, ennoble its shade and appearance as a whole. A few years ago, stains were used for these purposes that interacted with the upper layer of wood, as well as varnishes. The level of saturation of the pigment is determined only by the preference of the customer, who in advance stipulates the breed he needs in advance. But, despite the above advantages, the wood, which was processed by these compounds, has one significant drawback, the essence of which is that when damaged on the surface of the wood, a light spot is formed. This is due to the fact that the pigment penetrates only into the upper layers of wood, in connection with which, choosing between natural wood and material processed these compounds, give preference to the natural version.

As the finish processing of the door leaf, water -based acrylic varnishes are used, which, in contrast to alkyd varnishes on solvents, to less change the tone and structure of wood, and is also characterized by greater environmental friendliness. As for the choice between matte and glossy surfaces, it is important to note the fact that pollution is more visible on matte surfaces, while glossy surfaces hide the texture of wood, making the color more saturated. In this regard, we advise you to give preference to semi -gloss as well as semi -dummy coatings for phylene doors.

complete garbage, not instructions

complete garbage, not instructions